How to Cure Concrete and Developments in GPR

This post will discuss concrete curing in Australia, with a short review on Match Temperature curing. It will also review a case study that looks at the developments in GPR Software.

We have a busy year ahead of us and we have plans to attend a number of conferences and events. Please see the newsletter for a list of events we will be attending this year.

Concrete Curing in Australia

This article will discuss concrete curing in Australia, looking at relevant standards by state and then some of the risks for onsite sample collection and recovery in different climates. Finally, there will be a short review of a more specialized curing method, Match Temperature curing.

Preparation

The curing process is critical to ensuring representative and comparable concrete strengths, but the casting of the cylinders is as important for consistency as the curing environment. Compaction methods should be applied consistently, rodding the correct number of times or using a suitable concrete vibrating table or internal vibrator.

Curing Standards and Regulation

Curing Standards and Regulation

The main standard in Australia is "AS1012.8 - Methods of testing concrete Method for making and curing concrete - Compression and indirect tensile test specimens".

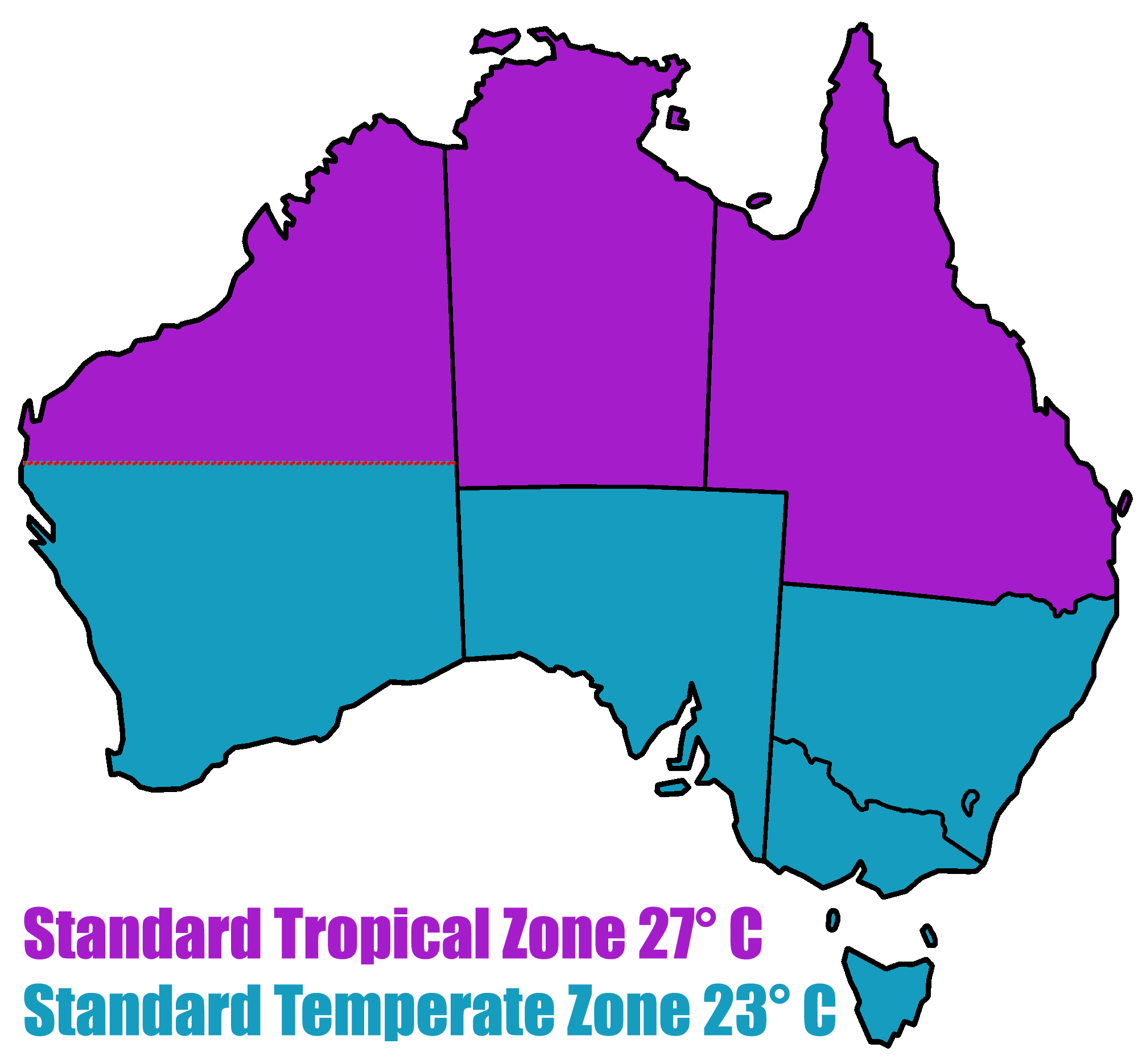

AS1012.8 defines a typical compression sample [1:2 cylinder, 100 or 150mm diameter]. Curing temperature is by region, with the Tropical zone curing at 27° C and the Temperate zone curing at 23° C. The illustration at right shows these zones.

Suitable curing environments may be via immersion in lime saturated water or in side of a fog room.

Differences between state are normally due to Test Methods defined by a local road authority, all of which do refer to AS1012.7 but clarify situations, a few notes by state are below.

- Main Road WA requires samples of steam cured elements be stored inside the steam curing enclosure, towards its based and away from any steam entry vents.

- QLD Transport and Main Roads requires temporary wet storage of samples onsite in lime saturated water. It also requires samples for precast elements are curried under the same condition as the element. Steam curing as in WA

- RMS T367 is a specific curing method to cure samples in similar conditions to a cast in situ pavement, it involves leaving samples uncovered and exposed to the elements, with the same curing compounds used on the pavement.

Curing on site

Specimens are normally retained in their moulds for 18h before moving into wet curing environments, in a lab preventing loss of moisture and controlling temperature is straightforward, samples stored on site are at much greater risk of incorrect curing unless steps are taken to protect them.

The minimum criteria by AS1012.8 is sample cylinders require a lid, storage away from direct sun or wind, and to be placed under an insulating cover. It further defines the purpose of these measures is to protect from loss of moisture and extremes of temperature.

The minimum criteria by AS1012.8 is sample cylinders require a lid, storage away from direct sun or wind, and to be placed under an insulating cover. It further defines the purpose of these measures is to protect from loss of moisture and extremes of temperature.

A temperature controlled storage box like an EZ cure by Engius will provide a central and safe storage environment for lidded cylinders. Research conducted by Engius shows a more reliable concrete strength value when cylinders are placed in a properly protected curing space.

Transport

Transport is the other large risk point, moulds should be similarly protected and moved into final wet curing as quickly as possible. Again, the risk here is loss of moisture or extreme temperatures.

Match Temperature Curing

Match temperature curing is a curing approachs with two additional aims, to better measure early age strength and to produce a final 28 day sample which better represents the real compressive strength of the concrete.

Match temperature curing is to quickly place the samples into a curing enviroment with the same temperature as a point within the concrete structure they represent. This is acomplished using temperature probe cast within the concrete element, then a match temperature curing tank will heat or cool its water to be this measured temperature.

Contraints to this technique are simmilar to using an accelerated curing procedure, samples need to be protected from direct contact with the curing water using a sealed cylinder case, and it is critical that the sensor probe is placed in a representative point of the structure, like an area of critical stress or a lifting point.

Contraints to this technique are simmilar to using an accelerated curing procedure, samples need to be protected from direct contact with the curing water using a sealed cylinder case, and it is critical that the sensor probe is placed in a representative point of the structure, like an area of critical stress or a lifting point.

A similar match temperature aproach is to place samples within a steam curing environment, or to plumb a water tank inline with the water supply to a large scale wet curing system so cylinders may be cured withing the heating water.

New Developments in GPR Software

The following Case Study is an interesting illustration of “Random Walk” GPR data collection. Data was collected on a series of golf green to show the position and depth of drainage used to keep them in top condition. Data was collected using a Noggin 1000 Smart Cart with Top Con SRG-1 GPS. The TopCon GPS is able to achieve about 1m accuracy.

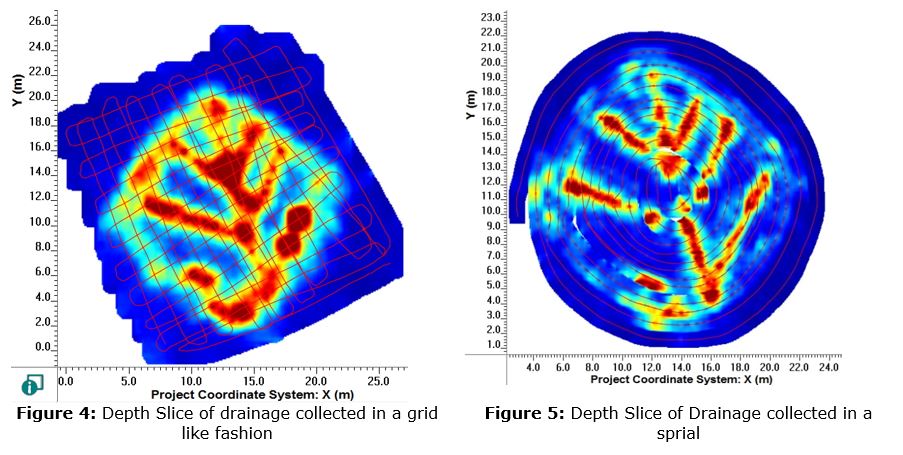

Two survey methods were chosen:

- The first entailed walking back and forth in both the X and Y directions with a spacing of approxiumately 1m. The path is shown in figure 2. This approximately matches the traditional path used in a grid scan, however the survey lines are not parallel or evenly spaced. Additionally the data was collected in one line.

- The second followed a spiral path starting in the center and spiralling outward and is shown in figure 3. This is very different to the traditonal method of scanning for a depth slice.

The images below are the resulting depth slices from each of the surveys. There are some general similarities. Firstly they both show the dendritic pattern of the draining pipes under the golf green. This shape generally has a central “stem” with multiple “branches” out from the stem. The resolution and clarity of figure 5 seems to be better (this was the data collected in a spiral).

So why is figure 5 much more refined? The probable answer is the quality of the migration of the data. Migration requires an accurate measurement of the propagation velocity in the ground. Velocity is generally measured using a curve fitting process whereby a projected hyperbola is matched to a target found in the data. The process is generally done to all of the hyperbolas found and the resulting velocity averaged.

The curvature of the projected hyperbola is adjusted until the “tails” match. When targets are not intersected at 90 degrees the shape of the hyperbola is effected, it becomes flatter, and so the velocity matching does not work very effectively. Looking at figure 4 we can see that the most targets were not crossed perpendicular to the path. The outcome is that the velocity would not be very accurate when determined using all of the hyperbola (i.e. they would all be flatter and hence the velocity calculated would be higher than the actual velocity). The offshoot of this effect is that the migration process does not work very well and the image is not very sharp. In figure 5 the targets are nearly always crossed perpendicular and so the velocity match is a lot more effective. The resulting image is much clearer.

Another outcome of this case study is the relative ease that a spiral path would have to collect. A rope would on a stake would provide all the guidance required to collect the data. On the downside, a spirally collected grid is restricted in terms of the shape of the area. A golf green is usually round or close to square but in many other instances the scan area may not be such a regular shape. So, the spiral grid scan is a tool the scanner can keep for some circumstances but may not be appropriate in all instances.