Concrete Sample Curing Tanks

Standard Curing Tanks

Standard Curing Tanks

In order for sample cylinders to undergo compression testing (and some other lab tests) they must be cured.

Curing involves immersing the samples in a water bath at least 8 hours after placing them into the sample moulds.

The primary purpose of curing is to ensure that all samples are similar with regards to quality and strength.

Australian Standards

The Australian Standard 1012 states:

Standard moist-curing conditions ensure that the concrete specimens made in the laboratory or in the field are kept wet and at a temperature of—

(a) 23 ±2°C, for the Standard Temperate Zone; or

(b) 27 ±2°C, for the Standard Tropical Zone.

Standard moist-curing conditions shall be provided by storing the specimen in lime-saturated water or in a fog room. Temperatures shall be recorded continuously, or the limits of temperature shall be recorded by a maximum/minimum thermometer.

The conditions shall be maintained at all times so that the specimens are kept within the appropriate temperature range specified in this Clause and so that the surfaces of the specimens are kept wet.

Care shall be taken to ensure that specimens are not exposed to streams of running water.

Curing Tank Range

Curing Tank Range

PCTE and Utest offer an array of curing tank options:

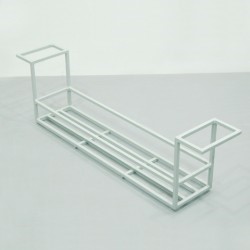

- The metal tanks (UTC-0950 large, UTC-965 small) are made from zinc coated sheet steel and supplied complete with base rack.

- The plastic (UTC-0960 large, UTC-0970 small) tanks are Polyurethane and have a bearer metal carcass and base rack.

Upon request, suitable upper racks to hold concrete cubes are available (max. 8 pieces). The tank is also supplied with a submersible circulator pump to ensure good temperature consistency.

The temperature is adjustable and can be kept constant by an electric resistance incorporating a digital thermo regulator which maintains the set temperature between ambient to 40 ºC with ± 2 ºC accuracy.

All Curing Tanks are supplied complete with:

All Curing Tanks are supplied complete with:

- Base Metal Rack

- Heater

- Submersible Circulation Pump

Heater

The thermostat fitted to this curing tank is designed to work with a band of 2°C. The heat input of 1000 watts is sufficient to maintain the temperature at 20°C under normal laboratory conditions approximating to 20°C and 50 % relative humidity. If the room temperature exceeds 20°C, use a portable cooler unit or cold water in order to set the curing at 20°C. Alternatively, if the room temperature is lower than 15°C, insulation of the tank is recommended in order to maintain the required temperature.

The thermostat fitted to this curing tank is designed to work with a band of 2°C. The heat input of 1000 watts is sufficient to maintain the temperature at 20°C under normal laboratory conditions approximating to 20°C and 50 % relative humidity. If the room temperature exceeds 20°C, use a portable cooler unit or cold water in order to set the curing at 20°C. Alternatively, if the room temperature is lower than 15°C, insulation of the tank is recommended in order to maintain the required temperature.

Tank Specifications

Steel Tanks

| UTC-0965 | UTC-0950 | |

| Internal Dimensions | 650 x 650 x 550 mm | 800 x 1500 x 550 mm |

| External Dimensions | 710 x 710 x 610 mm | 870 x 1600 x 550 mm |

| Weight | 55 kg | 90 |

| Capacity (100mm dia samples) | 36 (single layer) | 120 (single layer) |

Plastic Tanks

| UTC-0970 | UTC-0960 | |

| Internal Dimensions | 800 x 1100 x 550 mm | 700 x 1700 x 850 mm |

| External Dimensions | 915 x 1250 x 660 mm | 750 x 1830 x 960 mm |

| Weight | 60 kg | 110 kg |

| Capacity (100mm dia samples) | 88 (single layer) | 119 (single layer) |

Accelerated Curing Tank

UTC-0980-C

UTC-0980-C

The Accelerated Curing Tank is constructed to perform hot water curing of concrete sample to speed up curing, and therefore strength development. The unit has a capacity of 350L and the tank is made from stainless steel. The tank is then insulated with a double wall construction.

The temperature control is achieved with a PID controlled thermoregulator which has a ±3 o C accuracy. The system also has a timer.

Internal Dimensions 600 x 900 x 640 mm Approx Weight 70 kg Power 4500W

Curing Cabinet

| Internal Dimensions | 600 x 900 x 640 mm |

| Approx Weight | 70 kg |

| Power | 4500W |

UTCM-1100

The UTCM-1100 Curing Cabinet is used for curing of cement, concrete cubes or other mortar specimens. It can be used for curing cement specimens within the mould, or after removing from the mould. The curing cabinet provides 20 ± 1°C temp. and over 95% RH humidity for cement specimens. Internal chamber and racks are made of stainless steel. The temperature is maintained at 20 ± 1°C by a immersion heater and refrigerator unit which are supplied complete with cabinet. The cabinet is equipped with a digital control unit which controls and monitors the temperature.

We have upgraded our UTCM-1100 device and it now has an refrigeration system built-in. Our system has now 8 steps 9999 min; temperature control and humidity control. Ramps between 20 °C to 50 °C are possible and the humidity is able to reach 60% RH at 50 °C. The system excels at presets of 20 °C attaining 95 % Rh and is capable of 90% RH at 23 ± 2°C.

The humidity is maintained from 95% to saturation by water nebulizers and is also monitored on the digital control unit.

Internal Dimension 900 x 700 x 1350 mm External Dimension 1100 x 1000 x 2200 mm Weight (approx.) 150 kg Power 1200 W