Monitoring An Existing Structure

Asset owners with aging infrastructure are driven to gauge the remaining life of their structures. Corrosion monitoring is one way which gives the owner information about possible active corrosion and estimates of corrosion rate. There is a range of corrosion monitoring solutions for existing structures. The choice of corrosion monitoring system is dependent on the access and requirement of the asset owner. We have several options for existing structures, including: the CANIN+, CorroMap and Galvapulse for surface measurement of corrosion half potential and corrosion rate, as well as the CorroRisk and BGB Retro-fit probes which can be installed for corrosion rate monitoring.

CorroMap

The CorroMap provides easy to use half-cell potential measurement with many user-friendly features..The CorroMap is a rapid, non-destructive technique for the evaluation of reinforcement half-cell potentials. It maps the contour plots of half cell potential and resistance in colour on the screen for transfer to PC.

The CorroMap provides easy to use half-cell potential measurement with many user-friendly features..The CorroMap is a rapid, non-destructive technique for the evaluation of reinforcement half-cell potentials. It maps the contour plots of half cell potential and resistance in colour on the screen for transfer to PC.

Resipod

Surface resistivity measurement provides extremely useful information about the state of a concrete structure. Not only has it been proven to be directly linked to the likelihood of corrosion and the corrosion rate, recent studies have shown that there is a direct correlation between resistivity and chloride diffusion rate.

Surface resistivity measurement provides extremely useful information about the state of a concrete structure. Not only has it been proven to be directly linked to the likelihood of corrosion and the corrosion rate, recent studies have shown that there is a direct correlation between resistivity and chloride diffusion rate.

CorroRisk

The CorroRisk probe has been developed for use on existing concrete structures. The probe ensures that reinforcement corrosion can be predicted in good time before the actual initiation. This is due to a revolutionary inastllation of anodes at incremental depth on the concrete cover, therefore giving an understanding of the diffusion of contaminants to the reinforcing bar. The planning of the necessary maintenance can be optimised and the result is a lower cost of repair and fewer traffic obstructions. The CorroRisk probe is recommended to be used in all types of existing concrete structures, especially in aggressive corrosive environments and where visual inspection is difficult.

The CorroRisk probe has been developed for use on existing concrete structures. The probe ensures that reinforcement corrosion can be predicted in good time before the actual initiation. This is due to a revolutionary inastllation of anodes at incremental depth on the concrete cover, therefore giving an understanding of the diffusion of contaminants to the reinforcing bar. The planning of the necessary maintenance can be optimised and the result is a lower cost of repair and fewer traffic obstructions. The CorroRisk probe is recommended to be used in all types of existing concrete structures, especially in aggressive corrosive environments and where visual inspection is difficult.

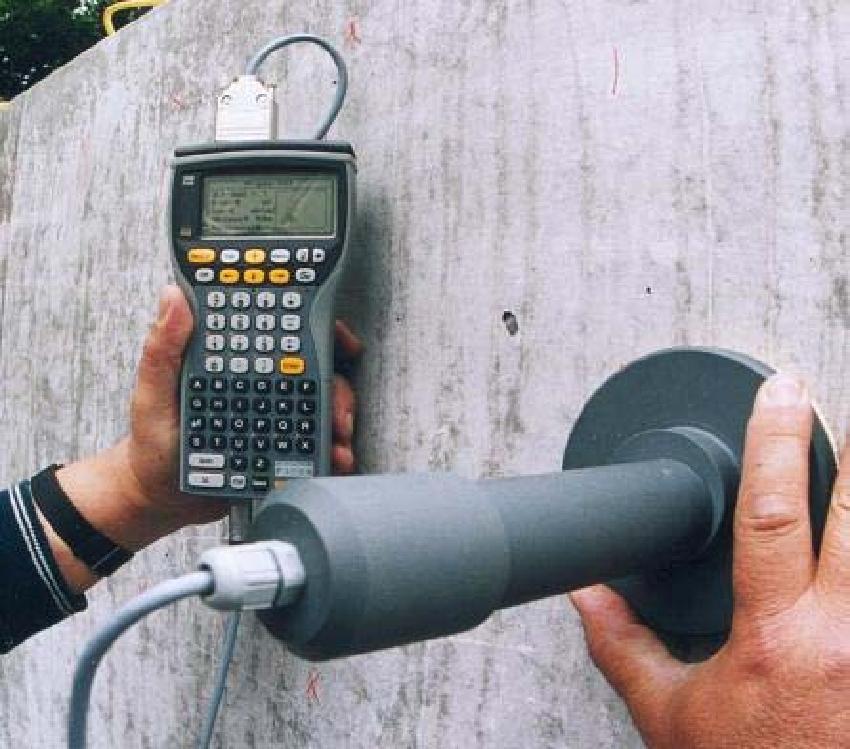

CANIN+ Electrical Reinforcement Potential

Firstly, accurate field potential measurements aid in detecting corrosion in rebars. Corrosion of steel in concrete is an electrochemical process. A potential field can be measured on the concrete surface by the use of an electrode, known as a half-cell, and a high-impedance voltmeter. The CANIN+ Corrosion Analyzing Instrument highlights corrosion activity before rust becomes visible. This early detection can be key in preventing an unanticipated structural failure.

Firstly, accurate field potential measurements aid in detecting corrosion in rebars. Corrosion of steel in concrete is an electrochemical process. A potential field can be measured on the concrete surface by the use of an electrode, known as a half-cell, and a high-impedance voltmeter. The CANIN+ Corrosion Analyzing Instrument highlights corrosion activity before rust becomes visible. This early detection can be key in preventing an unanticipated structural failure.

Galvapulse

The Galvanostatic Pulse Measurements technique (GPM) was first used in the field in 1988. It provides a solution to interpretation problems found when the half-cell potential methods is used in some environments, e.g. in wet concrete. Since the introduction development work has been conducted in order to use the technique to estimation of corrosion rate as well, which means how much reinforcement steel is being dissolved per year. Today, the GalvaPulse™ is a rapid, non-destructive polarization technique for the evaluation of reinforcement corrosion rate as well as half-cell potentials.

The Galvanostatic Pulse Measurements technique (GPM) was first used in the field in 1988. It provides a solution to interpretation problems found when the half-cell potential methods is used in some environments, e.g. in wet concrete. Since the introduction development work has been conducted in order to use the technique to estimation of corrosion rate as well, which means how much reinforcement steel is being dissolved per year. Today, the GalvaPulse™ is a rapid, non-destructive polarization technique for the evaluation of reinforcement corrosion rate as well as half-cell potentials.