Maintaining Standards with Utest Lab Equipment

One of the really interesting processes required when taking on a supplier like Utest has been the work we’ve done to customise their range for the Australian Market.

This customisation has happened on a number of levels:

- Assuring equipment fits the Australian Standards

- Customisation to fit the customer ergonomic expectations

- Augmenting systems to improve the operation of devices

Let me share with you some of the things we’ve been working on.

Ensuring Equipment Fits the Australian Standards

Most Utest equipment is supplied compliant to ASTM, EN or BS standards. So the process is to check the relevant standard against its Australian counterpart.

- The first thing to check off is the apparatus list to ensure they agree.

- Then the design is checked

- Additionally, the dimensions are compared. Conversions from Imperial to Metric are straight forward. The tricky part are the tolerances. Even where standards have the same dimension, they rarely have the same tolerances. So potentially they won’t be compliant.

- To ensure the manufacturing process isn’t making use of the tolerance a check must be done with a sample of the item.

- Following on from that each shipment must be checked to ensure the dimensions stay within spec.

We have a team in our warehouse, who have been trained to accept our stock as the containers arrive. The team includes our technician who works side by side with out store man to check each device for compliance. Checks include making sure we meet Australian Standards with regards to any electrical supply and that badging is correct and compliant.

Customisation to Fit the Customers Ergonomic Expectations

As we have travelled around Australia talking to lab technicians, it has become obvious that we must have the correct mould design. Ergonomics is incredibly important when you are using a device repeatedly. The little things count, and we’ve tried to incorporate that into the moulds we supply. Case and point is our cylinder mould design. The keys to a “good” mould are:

- Must have lever release

- The lid should be twisted off

- The mould should be easy to clean

- The mould should hold its shape

We think we have ticked a lot of those boxes with our new PCTE designed mould. Our new design should allow for easy cleaning and also index the junction point so that the mould returns to shape time and time again.

Augmenting Systems to Improve the Operation of Devices

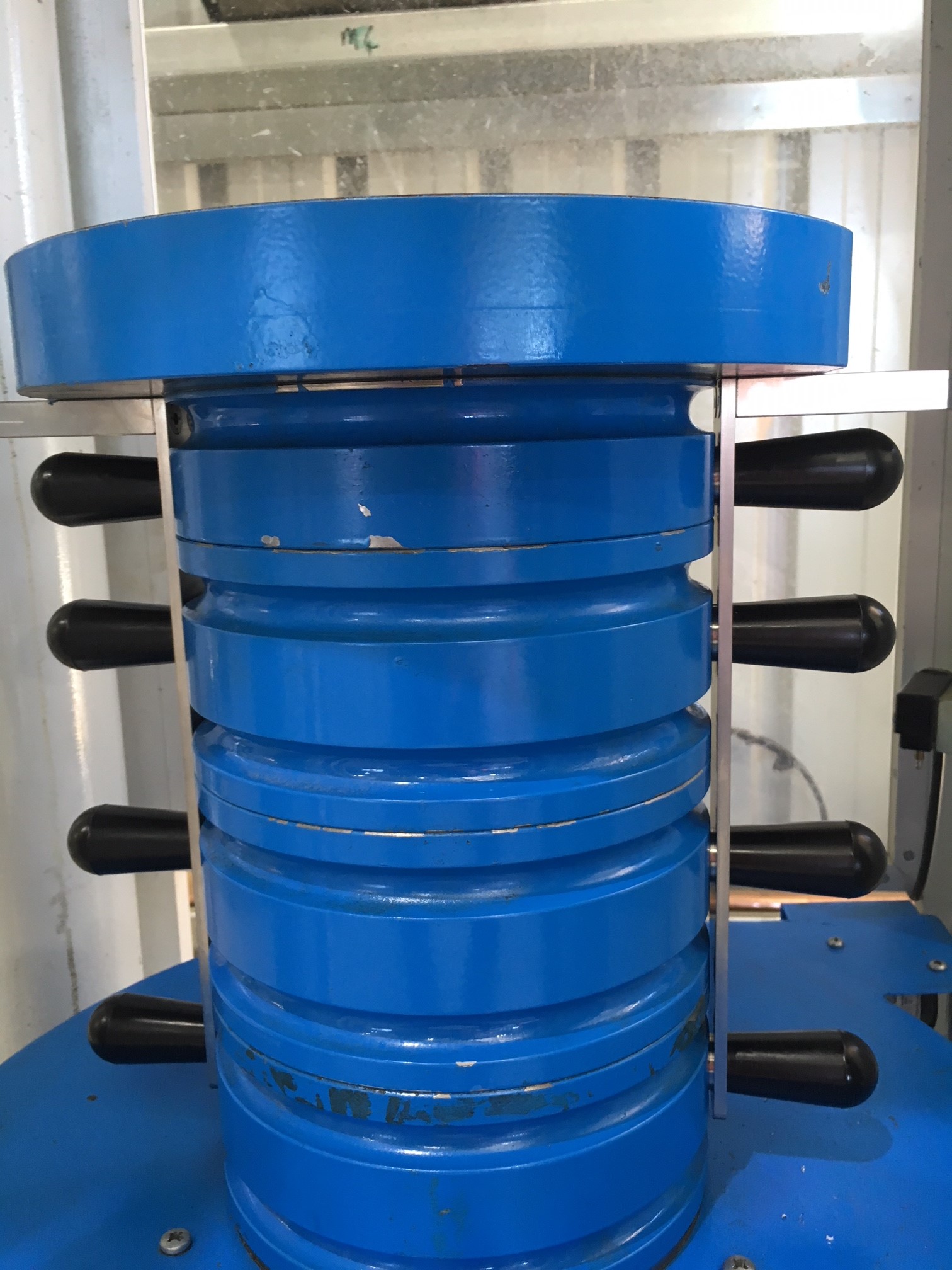

The Utest equipment is great design and quality at a good price, but we’re not afraid to add to the design to improve it. One issue we’ve noticed is quite common is the distance pieces jumping on some of our higher capacity machines. The standard design is a simple male and female mate between the pieces. If the jump they can be misplaced and when they are not put back in place the male part can be damaged.

We’ve taken it upon ourselves to design, with our mechanical team, a system that holds the distance pieces together as a monolith. Preventing the jump and the displacement. Talk to your local sales person about adding this customisation to your machine. Overall we are really hoping to demonstrate to our prospective customers the value that we can add to a system. We strive to go above and beyond for our customers.