Galvapulse - Surface Corrosion Rate System

The Galvapulse has now been replaced with the CorroMap.

The Galvanostatic Pulse Measurements technique (GPM) was first used in the field in 1988. It provides a solution to interpretation problems found when the half cell potential methods is used in some environments, e.g. in wet concrete. Since the introduction development work has been conducted in order to use the technique to estimation of corrosion rate as well, which means how much reinforcement steel is being dissolved per year. Today, the GalvaPulse™ is a rapid, non-destructive polarization technique for the evaluation of reinforcement corrosion rate as well as half-cell potentials.

The Galvanostatic Pulse Measurements technique (GPM) was first used in the field in 1988. It provides a solution to interpretation problems found when the half cell potential methods is used in some environments, e.g. in wet concrete. Since the introduction development work has been conducted in order to use the technique to estimation of corrosion rate as well, which means how much reinforcement steel is being dissolved per year. Today, the GalvaPulse™ is a rapid, non-destructive polarization technique for the evaluation of reinforcement corrosion rate as well as half-cell potentials.

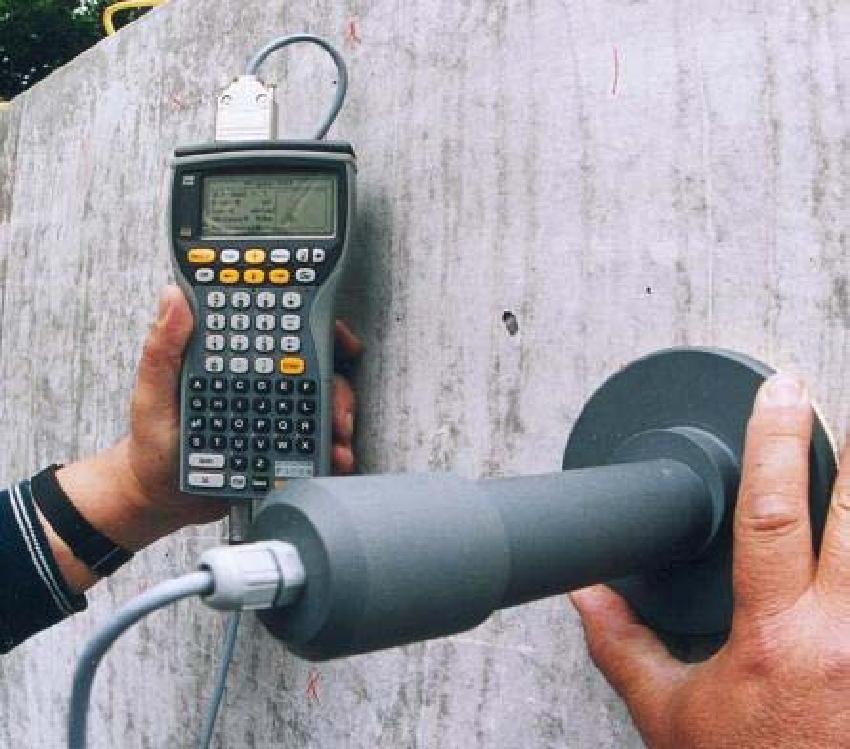

The GalvaPulse™ is a lightweight system supplied with batteries for optimum portability and is designed to be operated by one man. The GalvaPulse™ has typically been used in connection with:

- Swimming pools

- Bridges

- Balconies

- Parking houses

Advantages

- Estimation of the corrosion rate in the reinforcement can be made in less than 10 seconds.

- Reliable evaluation of reinforcement corrosion also in wet, carbonated or inhibitor treated concrete.

- Half cell potential and electrical resistance of the cover layer are given.

- Lightweight electrode / hand held computer and easy to operate software.

- Durable Guard Ring system for focusing the cur-rent field to the reinforcement.

- Measurements possible on uneven and curved surfaces.

Threshold values

For easy and quick evaluation FORCE Technology uses the following threshold values to categorise the risk of the corrosion rate:

Measurement |

Corrosion rate |

| < 0.5 µA/cm2 | Negligible |

| 0.5 - 5 µA/cm2 | Slow |

| 5 - 15 µA/cm2 | Moderate |

| > 15 µA/cm2 | High |

Above: Example of exposed corroding reinforcement.

Theory

Theory

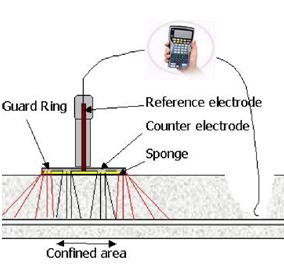

The GalvaPulse™ works by inducing a short duration anodic current pulse into the reinforcement galvanostatically from a counter electrode placed on the concrete surface together with a reference electrode.

To be able to measure the corrosion rate the electrode of the GalvaPulse™ has a “Guard Ring” to con-fine the current to an area equivalent to the central counter electrode, see Figure 2.

The Guard Ring is indispensable for the system in order to measure the effective polarization resistance and convert this to a corrosion rate.

Without the Guard Ring the area of the counter electrode would be much smaller than that of the working electrode (the reinforcement) and the electrical signal would have a tendency to vanish with increasing distance (cover).

Image: Sketch of GalvaPulse™ electrode

Estimating the corrosion rate

By utilizing the ohmic resistance (electrical resistance), the DC polarisation resistance over time, and the applied current, the corrosion current can be estimated with the Stern Geary equation.

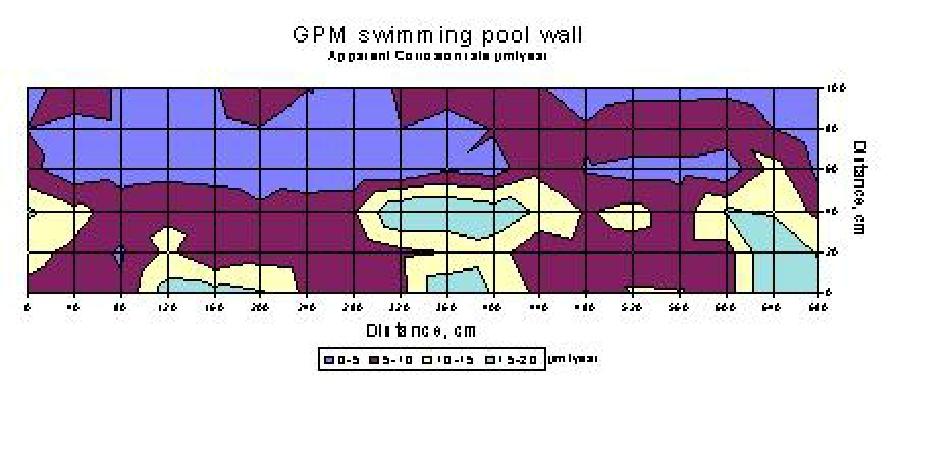

Example 1. Swimming pool

Swimming pool structures are often inspected using the GalvaPulse™. Here there is a high concentration of chlorides present and also humid and warm air. In Figure 3, corrosion rate values obtained on a swimming pool wall are shown as a colour plot.

Above: Presentation of the corrosion rate.

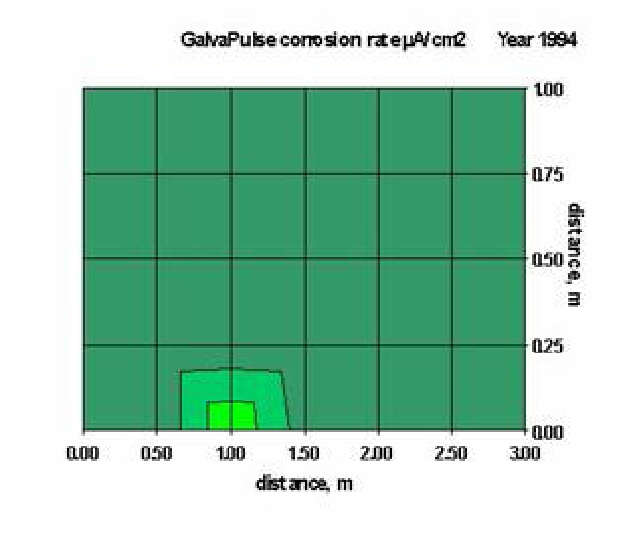

Example 2. Highway bridge pillar

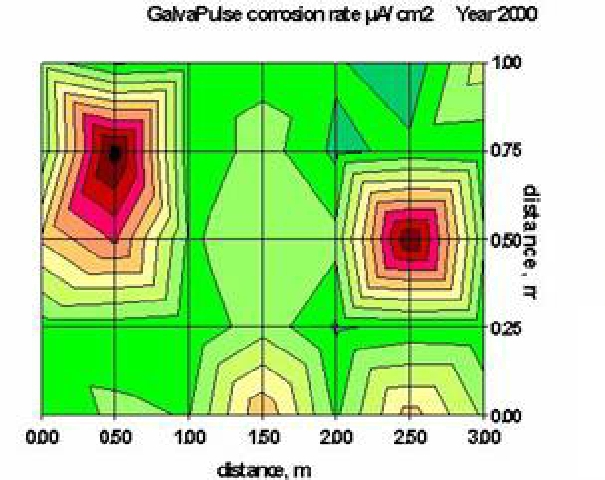

A highway bridge pillar has been monitored since 1994 with the GalvaPulse™ to evaluate the different stages of corrosion over time. Figure 4 and 5 shows the development in the corrosion rate from 1994 to 2000.

Left Image: GPM data from bridge pillar 2000

Right Image: GPM data from bridge pillar 1994