RPX INSITE

Concrete Temperature and Strength Testing Sensors

INSITE delivers critical concrete data so you can make better decisions.

INSITE delivers critical concrete data so you can make better decisions.

INSITE loggers record concrete temperature and calculate on site concrete strength using maturity.

The concrete maturity method is a proven early age strength estimation technique (ASTM C 1074) that accounts for the effects of time and temperature on the strength development of in-place concrete.

INSITE loggers are made for the world’s toughest construction projects. Providing critical temperature profile and strength information so the best decisions can be made at exactly the right time.

These rugged loggers are designed with redundant systems and high temperature components to ensure they survive in the hottest, harshest concrete environments.

INSITE strikes a perfect balance between wired and wireless technologies, resulting in increased reliability, global accessibility, and every-job affordability. When combined with intelligent cloud-based software, InSite puts the concrete data you need in the palm of your hand.

How INSITE works

INSITE loggers can run offline and be manually synchronised, or in real-time with continual connection to a Wireless Remote.

A single Base Station provides wireless coverage for a whole construction site using LoRa radio Just log in to your RPX account to access synchronized and live results from any PC or device.

Insite Loggers

Insite Loggers

Rugged InSite loggers gather the data you need to get the job done right and on-time.

These self-starting sensors detect fresh concrete and begin logging critical data at exactly the right moment.

Triple-redundant thermistors ensure the most precise temperature accuracy and provide peace of mind against data loss.

Temperature measurements are stored every 60 seconds for 180 days and concrete maturity is calculated using 1-minute temperature readings.

Insite Pocket Reader

Insite Pocket Reader

A simple option to activate, and collect data from self contained Insite Loggers.

The Pocket Reader connects to a WiFi network such as a phone hotspot, and downloads temperature data from Loggers, immediately uploading to Insite cloud software.

A Pocket Reader is able to connect to any number of loggers, downloading temperature and maturity data.

When required a reader may be used away from wireless networks, and manually uploaded later.

Insite Remotes

Data delivery you can trust and power you can rely on.

Data delivery you can trust and power you can rely on.

Insite Wireless Remotes use LoRa radios that extend ranges and use less power expanding your ability to send data and letting you worry less about keeping them going.

Remotes can be set to send data at different intervals so that you can gather critical data more often, or monitor less critical locations less frequently. All Remotes are powered by low-cost, easy to find AA batteries making them powerful and convenient!

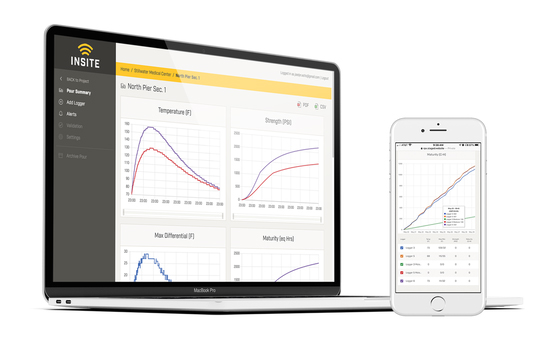

Insite Cloud Software

The InSite cloud-based software presents you with up to the minute concrete data. Current temperatures and strengths for loggers are easy to access and graph so you know exactly what is happening at any moment.

The InSite cloud-based software presents you with up to the minute concrete data. Current temperatures and strengths for loggers are easy to access and graph so you know exactly what is happening at any moment.

Alerts can be set to warn you of high or low temperatures, strength thresholds, differential temperatures when monitoring mass pours. All delivered to you via email or text.

Advantages over Concrete Thermocouples

INSITE loggers are more durable and simpler to operate than a thermocouple based system, benefits include:

- Automatic concrete maturity and strength calculation, information is available with no processing, site staff can read maturity and strength of concrete in RPX's INSITE Web App.

There is no need to load data into excel. - The most durable logger on the market, better temperature resitance, three redundant thermistor sensors and potting material chosen specifically to prevent water ingress.

- No Data Loss, each logger is self contained. There is no permanent connection to the remote box needed and even a damaged cable can be re-terminated easily

- No Programming, loggers are ready to run out of the box, with an automatic start function when the concrete is placed. Just scan or enter the serial number and connect to a remote them to add them to your RPX INSITE account.

- Simple Installation, rather than working with finicky and expensive thermocouple wire and calibrating, each logger only need be tied into place within the reinforcing cage and the cable led to a point outside the form work

Specifications

| Insite Logger | |

| Cable Length | 4.4 m (Default), 1.2 m & 9.1 m, Custom |

| Maturity Calculation | Nurse Saul or Arrhenius |

| Operating Temperature | -20°C to 125°C |

| Max Storage Time And Temperature | 85°C for 2 years |

| Max Temperature Measurement Range | -10°C to 110°C |

| Temperature Accuracy | ±1°C (-10° to 110°C) |

| Temperature Resolution | 1°C |

| Time Accuracy | 20 seconds per month |

| Measurement Rate | 1 minute (resolution for max/min) |

| Maturity Integration Period | 1 minute |

| Insite Wireless Remote | |

| Channels | Available in 1 and 4 channels |

| Powered By | 6 AA Batteries |

| Modulation | LoRa 900MHz Radio |

| Power Output | 18.5 dB m |

| Receiver Sensitivity | 123 dB m |

| Insite Wireless Base Station Specifications | |

| Radio Modulation | LoRa |

| Radio Frequency | 923.3 MHz |

| Power Output | 18.5 dB m |

| Antenna Type (gain) | PCB Trace (1.7dBi) |

| Over-The-Air Encryption | AES-256 |

| Power | Power-over-ethernet |

| Network Interface | RJ -45, 10/100 Base-T/TX Ethernet (IEEE802.3/802.3u) |

| IP Configuration | DHCP Only |

| Cloud Interface | Data pushed to cloud over HTTPS on port 443 |