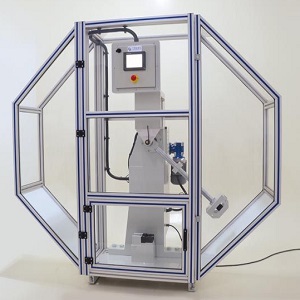

Motorized Pendulum Impact Tester

UTCI-0150

Impact testing determines the amount of energy absorbed by a material during fracture. This absorbed energy is a measure of a given material's toughness and acts as a tool to study temperature-dependent brittle-ductile transition. It is to determine whether the material is brittle or ductile in nature.

The UTCI-0150 Motorized Pendulum Impact Tester is a high-performance device and is ideal for testing metals to Charpy and Izod standards at capacity of 150 Joules. The machine's frames are manufactured from solid steel. The machine is safe and easy to operate. Accessories for Charpy and Izod tests can easily be fitted to the machine. Each test requires a specific vice/fixture, specimen adapters, and hammers. The coloured touch screen digital control unit collects and displays the test results.

Once the test is complete, the pendulum is automatically captured and returned to its starting position. This allows the starting angle to be changed according to the test, which enables optimum test parameters, such as impact speed, to measured.

Typical customers for impact testing systems are universities, automotive and aero companies and research labs.

MAIN FEATURES

- Available energy is 150J of Charpy and Izod testing

- Motor-driven raising of hammer with auto-return after test for increased productivity and operator safety

- Electromagnetic brake/clutch control mechanisms respond quickly for improved operation

- Conveniently located controls for efficient testing

- Clearance between supports of 40 mm,

- Fall angle is 150 degree,

- Suitable for specimens of 10 x 10 x 55 mm

- Cabin door sensitive automatic testing mode that enables the fast and continuous testing and manual mode for more control for the operator.

- Highly sensitive encoder to take the angle readings for every position of the hammer and to capture the very peak point of the rise angle.

- Direct verification menu to verify the losses and calculate the error as described in the standards (air resistance, bearing resistance, etc.).

STANDARDS FOR UTCI SERIES

- ASTM E23 Standard Test Methods for Notched Bar Impact Testing of Metallic Materials

- EN 10045 Charpy Impact Test on Metallic Materials

- ISO 148 Metallic Materials - Charpy Pendulum Impact Test

- GOST 9454 Impact Bending Test Method at Low, Room and High Temperatures

- Fixtures/strikers are available for each test standard as well as customized tests.

Technical Specifications

| UTCI-0150 | |

| Max. Absorbed Impact Energy | 150 J |

| Raised Angle | ≈ 150° |

| Max. Impact Speed | 5.25 m/s |

| Standard span | 40 mm |

| Size of specimen | 10 mm x 10 mm x 55 mm |

| Power supply | 1phs, 220V, 60Hz |

| Overall Dimensions | 2200 mm x 950 mm x 2100 mm |

| Weight ( approx. ) | ≈ 800 kg |

Main Accessories

- Pendulum (needed capacity),

- Specimen centering plate (U, V)

- Anchor bolts (M22x300mm): 4 pcs

- Safety closure

Optional Accessories

- Full close Aluminium alloy safe cabin,

- ASTM E23 striking edge (R8mm),

- Self centering tong for setting charpy test specimen

- Anvils and pendulums for Charpy, Izod and tensile impact testing,

- Temperature Chamber for impact specimen,

- Notch Cutter for impact specimen

- Low Temperature Freezers for impact specimens.