Marshall Testing Machines

Marshall Compaction Mould

- UTAS-0641A - Marshall Compaction Mould AS-NZS-2891.5-2015- 101.6mm

- UTAS-0646A - Marshall Compaction Mould ASTM 6"

The Marshall Compaction Moulds, which are made from galvanized steel, use automatic or manual compactors to create the Marshall specimens. The Compaction Moulds consist of a base plate, mould cylinder and a collar. The stocked Marshall mould conforms to AS NZS 2891.5 with a 101.6mm internal diameter.

Technical Specifications

| Ram Travel | 130mm |

| Screw Travel | 90mm |

| Dimensions | 280 x 280 x 520mm |

| Weight (approx.) | 28 kg |

Marshall /CBR / Proctor Specimen Extruder

UTGE-0080

The UTGE-0080 specimen extruder is used to extrude specimens from CBR, Marshall and standard & modified proctor moulds. The extruder has a capacity of 30 kN. The extruder comes complete with a manual, a hydraulic jack and 2x adaptors which are used to extrude specimens from 100mm and 150mm (inner diameter) Marshall, CBR and standard & modified proctor moulds.

Technical Specifications

| Dimensions | Weight | |

| UTAS-0641A | Ø120x170 mm | 3.5 kg |

| UTAS-0646A | Ø175x210 mm | 6 kg |

Automatic Marshall Impact Compactor

UTAS-0782A-T

Automatic Marshall Impact Compactors have been created to prepare bituminous specimens for Marshall Stability tests using a stable and rigid machine. There are considerable time and effort saved from using this machine. It is durable and easily maintained. It contains the woodblock as per AS NZS 2891.5 with the correct size and density. The impact mass, hard face and drop height all comply with the AS standard 2891.5

The UTAS-0782A-T model Compactor is used for the compaction of a single 101.6mm dia. Marshall specimens.

The machine includes a heavy-duty design that is not affected by the constant jarring caused during the compaction process. The compactors have been created with a mould fixing mechanism. This action also raises the hammer and allows for the simple removal of the mould. This feature enables the user to quickly raise the hammer and release the mould at the same time.

The conveniently positioned control panel consists of a start/stop button and an emergency stop button. The control panel also includes a direct reading counter which can be used to set the required number of blows. The user is able to supervise the number of impacts on an LCD display efficiently.

If the number of blows has been preset, the machine will stop automatically once the set amount of impacts have occurred.

The compactor can be factory installed in the UTAS-0083 soundproof safety CE security cabinet. The moulds have to be ordered separately

Manual Marshall Compaction Assembly 101.6mm

UTAS-0670

Marshall specimens can be prepared manually using the Marshall Manual Assembly machine. It also complies with AS2891.5 concerning the hard face size, drop weight, drop height and woodblock density and size.

The Manual Marshall Compaction Assembly is supplied complete with:

- Wooden Compaction Pedestal

- Steel Plate

- Mould Holder

- Hammer Guide

- Hammer

Automatic Marshall Stability Test Machine

UTAS-1056.ACPR

The UTAS-1056.ACPR 50 kN Capacity Automatic Marshall Stability Test Machine is used to determine the maximum load and flow values of bituminous mixtures.

The apparatus is a bench mounted compression frame that has been manufactured with a sturdy and compact two-column frame, with an adjustable upper crossbeam. The control unit houses drive motor and worm gear. the BC100 Data Acquisition and Control Unit allows the adjustment of the pace of the lower platen (6mm/min to 60mm/min). This means that the system is compliant with AS NZS 2891.5 which requires a pace of 51 +-1mm/min.

For safety, the travel of the lower platen is controlled by limit switches. The front panel of the machines includes up and down buttons which can be used to rapidly adjust the platen position. The device can also be hand-operated by a lateral hand wheel for calibration purposes.

A 50kN capacity strain gauge load cell is fitted to the upper crossbeam to measure stability values. Additionally, a 25 x 0.001mm linear potentiometric displacement transducer has been fitted to the breaking head to monitor displacement.

The Automatic Marshall Stability Test Machine is supplied complete with:

- Load Cell, 50 kN

- Linear Potentiometric Displacement Transducer with Bracket, 25 x 0.001 mm

- PC Software

- Connection Cable

- Hand Wheel for Manual Control

- Breaking Head, 101.6mm (6-inch breaking head ordered separately)

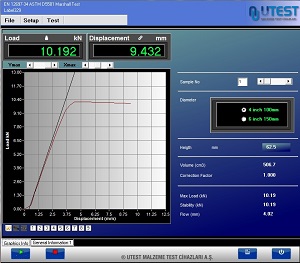

BC 100 Unit TFT Graphic Display Data Acquisition and Control Unit

The BC100 Unit is used to control the machine as well as process the data measured by the load-cells, pressure transducers or displacement transducers.

The BC100 Unit is designed with a front panel consisting of an 800x480 pixel, 65535 colour-resistive touch screen display and function keys. The unit two analogue channels: one the load cells and another for the displacement transducer.

The BC100 Unit has an easy to use menu. The user toggles the menu option and also enters numeric values to set the test parameters. The BC100 digital graphic display is able to draw real-time "Load vs. Time", "Load vs. Displacement" or "Stress vs. Time" graphs.

BC100 unit offers many additional features. You can save more than 10,000 test results in its internal memory. The BC100 unit also has support for various off-the-shelf USB printers, supporting both inkjet and laser printers. Thanks to its built-in internet protocol suite, every aspect of BC100 device can be controlled remotely from anywhere around the world.

Main Features

- Automatically calculates flow and stability values

- Displacement or limited load control

- Real-time display of test graph.

- CPU card with 32-bit ARM RISC architecture

- Permanent storage capacity up to 10000 test results.

- Four analogue channels, two channels are active for the Marshall test

- Programmable digital gain adjustment for load-cell, pressure transducers, strain-gauge based sensors, potentiometric sensors, voltage and current transmitters

- 1/256000 points resolution per channel

- 10 data per second sample rate for each channel

- Ethernet connecting for computer interface

- 800x480 resolution 65535 colour TFT-LCD industrial touchscreen

- Four main function keys

- Multi-language support

- Three different unit system selection; kN, Ton and lb

- Real-time clock and date

- Test result visualization and memory management interface

- Remote connection through Ethernet

- USB flash disc for importing test results and for firmware

- USB printer support for inkjet and laser printers (ask for compatible models)

- Camera support for real-time video recording during the test (ask for compatible models)

- Free of charge PC software for the test control and advanced report generation

Data Acquisition & PC Software

Marshall Test Software was developed for both EN 12697-34 and ASTM D5581 Marshall Tests. The Software includes control of machine, acquisition of load and displacement data, saving them and generating reports. The Software accepts specimen diameter and height as input parameters. It automatically calculates correction factors coming from the standards with respect to specimen size and calculates the stability factor. The Software continuously updates load and displacement until the end of the test. When the test is completed, the sharpest slope of the graph is calculated. The point that this line crosses the displacement axis is commented as an offset.

This offset is subtracted from the displacement value at peak point and flow. The report includes all these results for nine samples. The user can see 9 of the results on the same screen for easy comparison.

- Foreign Languag

e Support and Customizable User Interface Graphical data on the screen is refreshed simultaneously during the test procedure

e Support and Customizable User Interface Graphical data on the screen is refreshed simultaneously during the test procedure - Capable of accessing and manipulating previously test data

- Able to edit test parameters of the testing equipment through Software

- Graphical outputs and reports can be saved as an MS Excel worksheet

- Maximum flexibility to edit report and graph templates Foreign Language Support and Customizable User Interface

Technical Specifications

Platen Speed 6-60 mm/min Capacity 50 kN Dimensions 550 x 700 x 1200 mm Weight (approx.) 103 kg Power 1100 W