Front Loading Oedometer

UTS-0300

UTS-0300

To guarantee minimum frame distortion, the UTEST Front Loading Oedometer has been solidly constructed. The frame is designed to load the specimen through a lever arm assembly and one of three alternative beam ratios as 9:1, 10:1 and 11:1. The beam is fitted with a counter balance weight and beam support jack. The cell platform is compatible with the full range of UTEST consolidation cells and is fitted with a central spigot to ensure accurate centering of the cell under the loading.

The UTEST fixed ring consolidation cells are constructed from corrosion-resistant materials and conform to the requirements of the relevant standards. An integral water reservoir is incorporated in the cell which allows the specimen to be inundated when required. Upper and lower porous discs, a pressure pad and a cutting (specimen) ring are all supplied with the cells.

Test method

The consolidation attributes of soils of low permeability can be determined with the One-dimensional Consolidation test.

Tests are performed on specimens prepared from undisturbed samples or compacted disturbed samples. The user is able to estimate the behaviour of foundations under load with the data collected from these tests. Classification data and a knowledge of the soils loading history are also important in making these estimates.

- Undisturbed samples should be trimmed directly in the consolidation cell using the built in cutting edge and then further trimmed flush with top and bottom ends

- Mass of the cell and soil is measured and the wet mass of the specimen calculated by subtracting the known ring mass

- Pre dampened porous plates are placed on either side of the cell

- Cell is placed in loading Oedometer and a seating pressure is applied

- Pressure is doubled and changes in thickness are recorded periodically, this is repeated up to the maximum desired load

- Loading is continued until the thickness vs Log Time plot stabilises as described in AS1289.6.6.1 or to a time suitable to the sample and testing requirements

- The specimen is then unloaded and the change in thickness recorded

- Final mass is recorded and the specimen cut for examination.

- The sample is then oven dried to obtain the dry mass as per AS1289.2.1.1

Standards

AS1289.6.6.1

BS 1377:5

ASTM D2435

D3877

D4546

AASHTO T216;

System Components

System components that should be ordered separately include:

- Consolidation cell

- Dial gauge

- Displacement transducer and data logger

- Bench

- Weights

- Apparatuses for the preparation of consolidation samples

- Calibration disc

Data Acquisition & PC Software

4 or 8 channel static uniloggers (UTG-0320 or UTG-0325) are used for recording displacement data over time.

- High resolution: 260.000 points.

- Serial port for PC and printer connection.

- CPU card by microprocessor 32 bit ARM risk architecture.

- 4 or 8 analogical channels for displacement transducers.

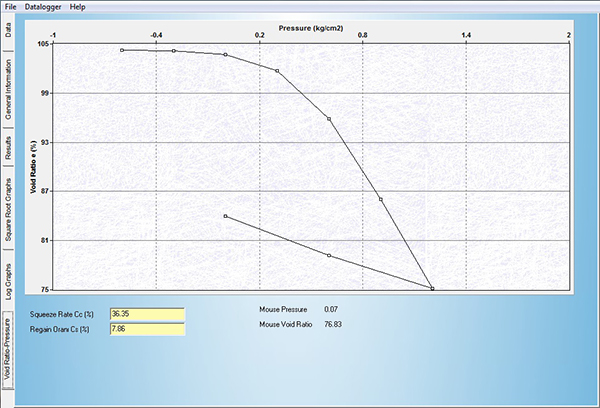

- The Utest consolidation software is developed according to ASTM D2435, D3877, D4546, BS 1377:5 and AASHTO T216 standards to use with static unilogger systems. The displacement transducers are connected to unilogger and unilogger is connected to PC by RS232 serial output. The software is capable monitoring the chance of displacement data over times. The user can start recording of vertical displacement and stop current recording proses. The user can enter time intervals (or select fixed time intervals) and stress for calculation consolidation test data.

The consolidation software has 8 different columns which can be set to different load values. The vertical displacement can be manually entered into these columns. The time-displacement pairs are drawn to square root time and logarithmic time graphs. The software can calculate engineering terms like as square root t90, t50, t100, mv, Cv. These calculations are done respect to the standards requirements by using best line algorithms. Since these parameters require an engineering perspective while making comments, all test data and graphs are exported to Microsoft Excel for further investigations.

The consolidation software has 8 different columns which can be set to different load values. The vertical displacement can be manually entered into these columns. The time-displacement pairs are drawn to square root time and logarithmic time graphs. The software can calculate engineering terms like as square root t90, t50, t100, mv, Cv. These calculations are done respect to the standards requirements by using best line algorithms. Since these parameters require an engineering perspective while making comments, all test data and graphs are exported to Microsoft Excel for further investigations.

- Foreign Language Support and Customizable User Interface

- Graphical outputs and reports can be saved as a MS Excel worksheet

- Maximum Flexibility to edit report and graph templates

Specifications

Cell Model and typical loads applied

| Cell Model No. | UTS-0307 | UTS-0309 | UTS-0313 |

| Specimen Diameter | 50 mm | 63.5 mm | 75 mm |

| Specimen Area | 1963 mm² | 3165.2 mm² | 4416 mm² |

| Beam Ratio | 10:1 | 11:1 | 9:1 |

| Total Load | 64 kg | 64 kg | 80 kg |

| Stress | 32 kg/cm² | 19.53 kg/cm² | 16.3 kg/cm² |

| Stress for 1kg | 0.5 kg/cm² | 0.34 kg/cm² | 0.2 kg/cm² |

Weight Sets

| Product | Sets of Weights for Consolidation | |

| UTS-0368 | 16 kg Set | (2) 5 kg, (1) 2 kg, (2) 1 kg, (3) 0.5 kg (2) 0.25 kg |

| UTS-0370 | 32 kg Set | (1) 10 kg, (3) 5 kg, (2) 2 kg, (1) 1 kg, (3) 0.5 kg, (2) 0.25 kg |

| UTS-0372 | 50 kg Set | (3) 10 kg, (2) 5 kg, (3) 2 kg, (2) 1 kg, (3) 0.5 kg, (2) 0.25 kg |

| UTS-0374 | 64 kg Set | (4) 10 kg, (3) 5 kg, (2) 2 kg, (3) 1 kg, (3) 0.5 kg, (2) 0.25 kg |

| UTS-0648 | 80 kg Set | (6) 10 kg, (2) 5 kg, (3) 2 kg, (2) 1 kg, (3) 0.5 kg, (2) 0.25 kg |