Concrete Cylinder Grinder

Automatic Grinding Machine

Automatic Grinding Machine

UTC-1060

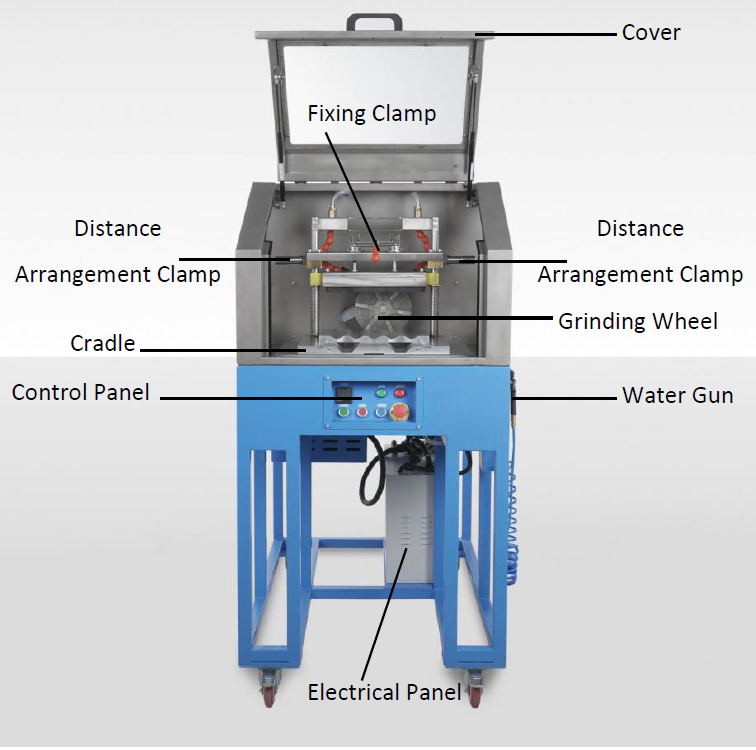

The UTC-1060 Automatic Grinding Machine provides fast grinding of concrete, rock, natural stone. etc. specimens to obtain plane and parallel surfaces according to EN and ASTM standards.

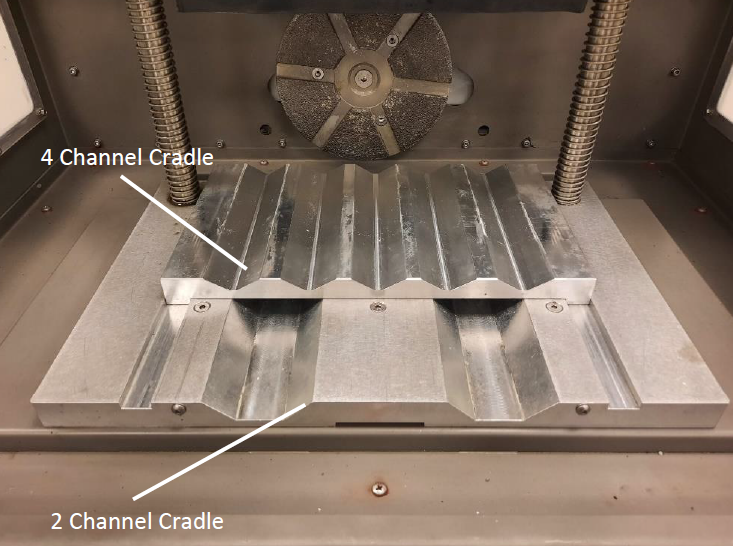

Five units of Ø38 to 50 mm cylinders, three units of Ø70 mm to Ø110 mm cylinders, two units of Ø110 mm to Ø160 mm cylinders,can be ground simultaneously with the suitable cradle.

Application

- Concrete strength grade of 80 MPa or less, single end grinding achieves constant results.

- Concrete cylinders with double end grinding method gives constant compressive strength values for all strength grades.

- Grinds planeness and parallelism of test cylinder ends in accordance with ASTM standards C31, C39, C-192, and EN 12390-3,12390-1, 12504-1.

- Ready to use for 150 x 300 mm test cylinders and for 100 x 200 mm test cylinders (includes adaptor).

- Automatic bi-directional radial displacement of the table.

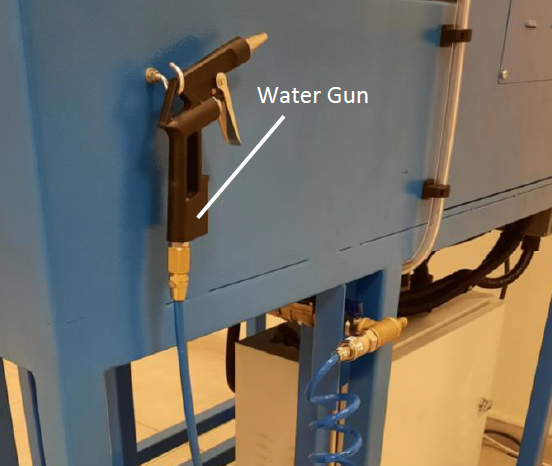

Water Recirculation Tank

Water Recirculation Tank

An optional UTC-1064 water tank with a filtration and circulation system is available. This water tank is ideal for operating a cylinder grinder in laboratories that do not have a water treatment system.

Automatic Operation

A Programmable Logic Controller (PLC) manages the machine and all its automatic controls. The PLC is essentially the grinding machine's brain, as it controls all its functions. The control panel of the device consists of timer unit, run and alarm lights and start-stop-reset-emergency stop buttons.

stop buttons.

Timer: The timer controls the duration of the full cycle. The grinding time is determined for each sample according to material hardness and cylinder diameter. The timer is set in seconds only.

Accessories

- Adaptor for 100 x 200 mm test cylinders

- Adaptor for 150 x 300 mm test cylinders

- Adaptor for 150mm test cube

- Diamond-grinding wheel included

- User Guide

Features

• Control Box: Programmable Logic Controller

• Variable Speed Drive: The machine is equipped with three (3) variable speed

• Timer: The duration of the full cycle is controlled by the timer. The material hardness and cylinder diameter both determine how long the grinding time for each sample will be.

• Emergency Button: When this emergency button is activated, all controls are inhibited and the machine cannot be restarted until the button is released.

Positioning of Cylinders

There are parameters that need to be taken into consideration before you set any cylinder into a compression test. A cylinder grinder can easily fix this kind of setback.

The sample adaptor (included) is placed on top of the displacement table.

Melting Pot

UTC-1070

UTC-1070

The melting pot is used for the preparation of capping compound. This is generally a Sulfur compound which is used to produce squared-off ends. The pot has a capacity of 3L and an Aluminium container in a well-lagged steel jacket. The pot is also supplied complete with a cover and a thermostatic ally controlled heating system. The heating system is capable of keeping a constant temperature of 200 deg C.

Technical Specifications

| Dimensions | 350 x 320 x 290 mm |

| Capacity | 3L |

| Power Consumption | 600 W |

| Weight | 9 kg |

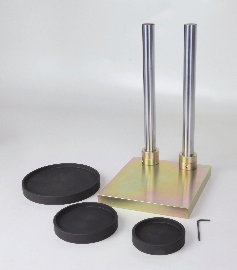

Capping Frame

UTC-1074

The Cylinder Capping Frame is used to ensure that the planned end surfaces are perpendicular to the axis of the cylinder. The frame comprises of a 75, 100, and 150mm dia base plate, making it useful for most samples including cylinders and cores.

Laboratory Core Trimmer and Cut-Off Machine

UTR-0300-T

ASTM D4543

The UTR-0300-T takes irregular pieces of rock or core, and transforms them into perfectly machined shapes (cubes, prisms, etc.).

The machine includes a vice that holds the samples in place, and a second V shaped vice is then used to cut the cores to a maximum size of 75 mm diameter and 140 mm height. The samples can be turned upside down in the vice and this will produce longer cores. The machine includes a cooling water inlet.

UTR-0300-T for 60 Hz with 220 V or 100 V can be supplied.

Technical Specifications

| Dimensions | 730 x 1050 x 590 mm |

| Weight (approx.) | 100 kg |

| Power | 1100 W |