Universal Testing Machines

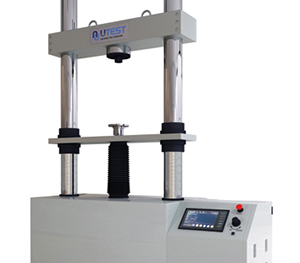

Suitable for multiple testing applications, universal testing machines are able to perform tensile and compressive testing. Accessories support other tests such as CBR and flexural tests in selected models.

Suitable for multiple testing applications, universal testing machines are able to perform tensile and compressive testing. Accessories support other tests such as CBR and flexural tests in selected models.

All system are automatic and supplied with suitable control systems and hydraulic or motor stages.

A system will typically include platens suitable for compressive testing of specimens appropriate to the maximum load of the machine and a set of jaws for holding tensile tests samples.

Servo Hydraulic Universal Testing Machines

Computer controlled servo hydraulic universal testing machines are suitable to test various metallic and non-metallic materials and can carry out tension, compression, flexural and bending tests.

Features

- Closed Loop Servo controlled power packs

- Standard models offer dual test spaces for compression and tension testing.

- UTEST-S Series Universal Testing Machines are high capacity systems with a single test space, the jaws may be fitted with compression platens or bending apparatus as required.

- On all models a load cell is used for load measurement. Strain measurements are done by the electronic displacement transducers built in the machine.

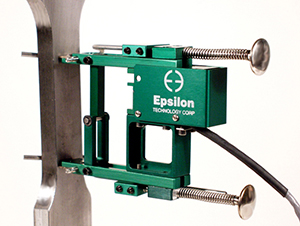

- Displacement or strain measurement can also be via an external extensometer fitted to the specimen.

- Rigid 4 column construction

- Supports load or displacement control

Accessories include: Multifunction Remote Control, Automatic Extensometer, Flexural Assembly, Compression Test Platens, High Temperature Cabinet

Specifications

| Technical Specification | |||

| Type | UTM-6060.SVD2 | UTM-6100.SVD2 | UTM-6200.SVD2 |

| Maximum Load | 600kN | 1000kN | 2000kN |

| Load Measurement Accuracy | 1% from 2% of max capacity | 1% from 2% of max capacity | 1% from 2% of max capacity |

| Displacement Resolution | 0,01 mm | 0,01 mm | 0,01 mm |

| Control Mode (Pace Rate Type) | Displacement and Load Control | Displacement and Load Control | Displacement and Load Control |

| Tensile Space | 750 mm | 750 mm | 1000 mm |

| Compression Space | 620 mm | 620 mm | 850 mm |

| Max Horizontal Test Space | 480 mm | 570 mm | 840 mm |

| Piston Stroke | 250 mm | 250 mm | 250 mm |

| Max. Crosshead Speed | 200 mm/min | 200 mm/min | 280 mm/min |

| Flat Jaw Faces | (0-15) and (15-30) | (0-30 and (10-40) | (10-40) and (40-70) |

| Round Jaw Faces | (Ø8-14), (Ø13-26) and (Ø26-40) | (Ø9-20), ,(Ø20-40) and (Ø40-60) | (Ø16-31), (Ø31-46) and |

| Compression Platen Size | 128x30 mm diameter | 145x40 mm diameter | 200x60 mm diameter |

| Bending Fixtures ( * ) | UTC-6069 | UTC-6169 | UTC-6269 |

| Power Supply | 380 V, 50 Hz, 3 ph OR 220 V, 60 Hz, 3 ph (2.5 kW) | 380 V, 50 Hz, 3 ph OR 220 V, 60 Hz, 3 ph (3.5 kW) | 380 V, 50 Hz, 3 ph OR 220 V, 60 Hz, 3 ph (3.5 kW) |

| Frame Dimensions | 770 x 600 x 2150 mm | 900 x 650 x 2400 mm | 1300 x 900 x 3250 mm |

| Frame Weight | 2600 kg | 3700 kg | 8800 kg |

| Max. Frame Height | 2550 mm | 2780 mm | 3500 mm |

| Power Pack Dimensions | 570 x 800 x 1020 mm | 570 x 800 x 1020 mm | 570 x 800 x 1020 mm |

| Power Pack Weight | 250 kg | 250 kg | 250 kg |

| (*) Bending fixtures whose technical specifications are given in the table below should be ordered separately. | |||

| ( * * ) Round Jaw Face Set, Ø60-80mm for UTM-6200.SVD2,should be ordered separately | |||

| Technical Specifications for Bending Fixtures | |||

| Code | UTM-6069 | UTM-6109 | UTM-6209 |

| Max Load | 600 kN | 1000 kN | 2000 kN |

| Bending span | 30-500 mm | 50-500 mm | 50-720 mm |

| Roller Diameter | Ø30 mm | Ø50 mm | Ø50 mm |

| Roller length | 120 mm | 160 mm | 160 mm |

| Bending Depth | 100 mm | 180 mm | 180 mm |

Hydraulic Universal Testing Machine - UTM-4000.FPR

The Hydraulic universal test machine is intended mainly for testing ferrous samples, it will also support compression testing up to the machines maximum load rating.

The Hydraulic universal test machine is intended mainly for testing ferrous samples, it will also support compression testing up to the machines maximum load rating.

Features

- Tensile test for samples up to 40 mm flat and 8 – 32 mm round samples

- Load measured by load cell, strain by inbuilt displacement transducer or external extensometer

- Dual test spaces for compression and tension testing

Specifications

| Technical Specification | ||

| Capacity | 600 kN | |

| Test Speed | 2mm/min - 25mm/min | |

| Load Measurement Accuracy | ± %1 | |

| Displacement Measurement Resolution | 0,01 mm | |

| Columns Diameter | Lower | 70 mm |

| Upper | 70 mm | |

| Vertical Test Distance | Tension | Minimum 40 mm, Maximum 320 mm |

| Compression | Maximum 110 mm | |

| Distance Between Columns | 450 mm | |

| Piston Stroke | 150 mm | |

| Max Pressure | Grips | 350 bar |

| Load | 200 bar | |

| Weight | 1850 kg | |

| Height | 2700 mm | |

| At the maximum stroke | 2850 mm | |

Automatic Tension and Compression Machine - UTM-3000.FPR

Designed for civil engineering labs with a focus on concrete and reinforcing steel testing, the Automatic Tension and compression machine marries UTest’s BC100 automatic control system with a versatile welded steel frame

Designed for civil engineering labs with a focus on concrete and reinforcing steel testing, the Automatic Tension and compression machine marries UTest’s BC100 automatic control system with a versatile welded steel frame

Features

- Tensile test for rebar up to 22 mm, flat samples max 14 mm thick by 50 mm wide

- Compression testing of cylinders and cubes of up to 150mm dimensions

- Load measured by pressure transducer, strain by linear potentiometric displacement transducer

- Double acting piston with over travel protection

- Load rating between 1 kN/s to 20 kN/s

- BC100 controller can control a second test frame

Specifications

| Technical Specification | |

| Load capacity in tension | 500 kN |

| Load capacity in compression | 1000 kN |

| Max. vertical clearance with compression test accessory | 768 mm |

| Max. distance between grips, excluding piston travel | 268 mm |

| Distance between columns | 305 mm |

| Max. ram travel | 100 mm |

| Resolution digital display | 0.01 kN-mm |

| Load measurement Accuracy (starting from the first 10% of load range) | ± 1% |

| Strain measurement Accuracy | 0,01 mm |

| Overall dimensions approx. | 1660x800x500 mm |

| Weight approx. | 535 kg |

Electromechanical Universal Test Machine

The electromechanical universal test machine is a highly versatile test machine, intended for lower strength compression and tension test applications.

The electromechanical universal test machine is a highly versatile test machine, intended for lower strength compression and tension test applications.

The machine is supplied complete with high precision load cell. Gripping systems, platens, extensometers and other test accessories are not included and have to be ordered separately.

Features

- System supports load or displacement control

- Wide range of accessories available for concrete, soil, asphalt, cement and wood testing

- Pressure measurement by load cell, displacement by encoder connected with motor

Specifications

| UTM-8100.SMD2 | UTM-8300.SMD2 | |

| Max. Load | 100 kN | 300 kN |

| Max. Vertical Test Space (without accessories) Lower crosshead at middle stroke. | 650 mm | 850 mm |

| Distance Between Columns | 440 mm | 630 mm |

| Crosshead Travel | 400 mm | 200 mm |

| Test Speed Range | 0-100 mm/min. | 0-75 mm/min. |

| Load Rate | 0,001-2 kN/s (Depend on specimen stiffness) | 0,001-10 kN/s (Depend on specimen stiffness) |

| Machine Class | Class 1 starting from 1% of the capacity | Class 1 starting from 1% of the capacity |

| Encoder Resolution | 0.001mm | 0.001mm |

| Encoder Accuracy | 0,01 | 0,01 |

| Overall Dimensions | 1300x520x2300 mm | 1100x450x1860 mm |

| Weight Approx. | 400 kg | 800 kg |

Electromechanical Machine Accessories

The Electromechanical Universal Test Machine supports a comprehensive array of testing accessories which support the following tests:

- Steel – Rounds and Flats

- Tensile tests under load or displacement control

- Cement and Mortars

- Compression tests under load control

- Flexure tests under load control

- Tensile adhesion strength (Adhesives for tiles, repair, rendering and plastering)

- Concrete

- Flexure tests on concrete beams under load control

- Flexure tests on concrete kerbs under load control

- Splitting tests on concrete cylindrical and cubes specimens, and concrete paving blocks under load control

- Concrete, Natural Stone and Clay

- Flexure tests on clay roofing tiles

- Flexure tests on natural stone and kerbs

- Flexure tests on concrete terrazzo tiles

- Flexure tests on concrete paving flags

- Flexure tests on slabs of natural stone for external paving

- Flexure tests on glass fibre reinforced

- Cement (Precast concrete products)

- Punching tests for clay blocks

- Soil

- CBR under displacement control

- Quick triaxial tests

- Bituminous Mixtures

- Marshal test under displacement control

- Indirect tensile splitting tests

- Duriez tests under displacement control

- Insulation Materials

- Tensile strength and tensile bond strength perpendicular to faces

Extensometer Options

Different types of extensometers with accuracy of up to ±0.1 % of the indicated value are available depending on requirements. Extensometers separate to grips or platens can directly measure deformation of specimens.

Different types of extensometers with accuracy of up to ±0.1 % of the indicated value are available depending on requirements. Extensometers separate to grips or platens can directly measure deformation of specimens.

All systems can directly interface with an external extensometer, some systems also support the use of video extensometers.

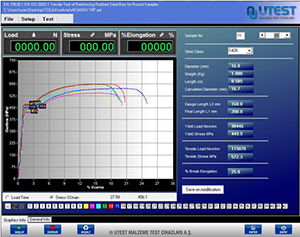

Software

Test software provides fully customized parameter definition, test method development tools, automatic test control, data collection, results analysis, and reporting.

Test software provides fully customized parameter definition, test method development tools, automatic test control, data collection, results analysis, and reporting.

Data collected may include client details, test type, specimen type and user info. The user can prepare his own report or export to Microsoft Excel. This flexible software solution supports multiple testing technologies and test types.

Advanced templates for testing to standards for tension testing, compression testing, flexure testing, and more across a wide variety of materials and applications help ensure quick and efficient test setup and execution. Up to 500 test methods can be managed at the same time.

Software Features

- Foreign language support and customizable user Interface

- Capability to save 24 test results of different specimens in one test record

- Graphical data on the screen is refreshed simultaneously during test procedure

- Able to save frequently used text snippets in memory and recall them when necessary

- User can access any data of previously completed tests for refresh and inclusion in new reports

- Able to edit test parameters of the testing equipment through Software