Schmidt Hammer

The SCHMIDT Hammer is the most frequently used method worldwide for non-destructive testing of concrete and structural components. It is best suited to relative concrete strength and quality.

The SCHMIDT Hammer is the most frequently used method worldwide for non-destructive testing of concrete and structural components. It is best suited to relative concrete strength and quality.

After the spring in the hammer is loaded, the test hammer strikes concrete at a defined energy.

The height of the rebounded mass is recorded and measured as an "R" value, this value is dependent on the hardness of the concrete.

By reference to conversion tables, the rebound value can be used to determine the corresponding compressive strength.

No other manufacturer offers such a broad range of impact energy and hardware types. Each hammer is designed for specific test applications.

Original Schmidt Live

The Original Schmidt Live, OS8000 is the original concrete test hammer by Proceq, now digitally redefined as the most advanced R-value hammer ever made, with unmatched performance, ease of use, and versatility.

Paired with a user-friendly mobile app, the Original Schmidt Live OS8000 increases operator productivity and makes instantaneous reporting possible, from anywhere, any time.

Original Schmidt Live Package

The Original Schmidt Live is available as a package combining the best in class hardware OS8000 and a 5 year subscription to the OS app. The App subscription may be continued after 5 years, or alternatively the Schmidt Hammer may be used only as a stand a lone device. This package also includes a 5 year electrical 6 month mechanical warranty.

Mechanical Original Schmidt

The original schmidt mechanism is a pure mechanical design, with measurements based on a physical sliding indicator.

The original schmidt mechanism is a pure mechanical design, with measurements based on a physical sliding indicator.

In addition to the modern data logging options, the same Silver Bullet mechanical design is manufactured to this day. Ideal for users who only need ocasional measurements, without recording their results.

When performing a Schmidt Hammer Test, it is critical that the hammer be held at right angles to the surface. The orientation of the Hammer will in turn affect the rebound reading, and different calibration curves are required by orientation.

Original Schmidt Type NR/ LR

With this model Rebound values are recorded as a bar chart on a paper strip. One roll of paper strip offers room for 4000 test impacts.

Pendulum Schmidt Hammer

Type PT (Concrete Test Hammer)

Equipped with a larger plunger surface, it is especially designed to test on softer material such as light weight concrete, gypsum boards and on fresh concrete. It is often used to determine the right time to remove formwork.

Type PM (Mortar Test Hammer)

Designed to test the mortar joints in brickwork. It has a specially developed plunger whose shape ensures the impacts are applied to the surface of the joint, the contact point has a diameter of 8.0 mm. Based on the rebound values the mortar quality can be classified.Concrete Compressive Strength Range

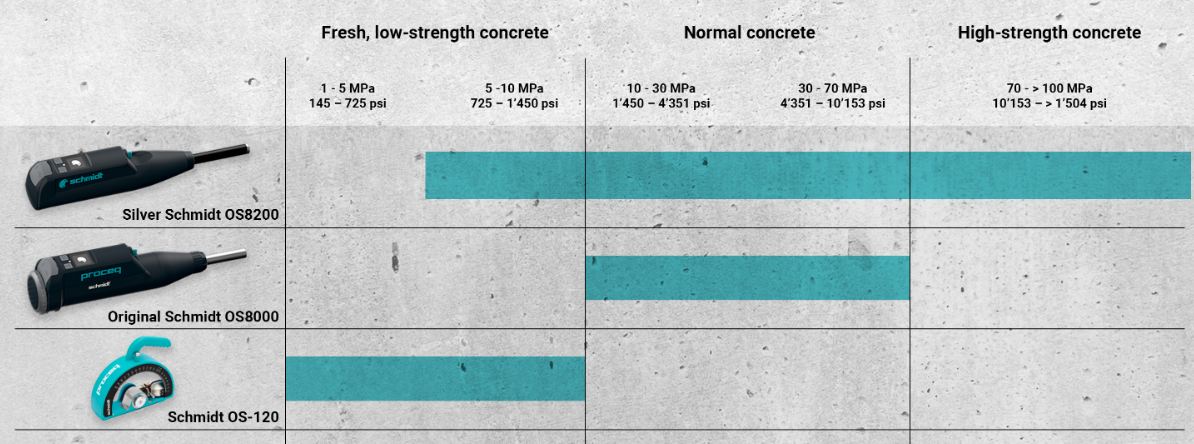

Each rebound hammer is built for a different purpose, the following table gives an overview of the standard strength ranges and applications for each instrument.

Impact Energy of Original Schmidt Mechanisms

Type N

This is the workhorse of the range. With a measuring range 20 to 70 MPa compressive strength and impact energy of 2.2J, this hammer is sufficient for most engineering applications. Rebound values are read from a dial and converted to compressive strength using the graphic above it.

Type L

Also with a measuring range 20 to 70 MPa compressive strength, this hammer has an impact-energy, which is three times smaller than the Type N. These types are used for testing thin walled (< 100 mm) or small components but also cast stone components sensitive to impact.

Test Anvils

Each test hammer should be checked after 1000 test impacts. A testing anvil is used to check whether the rebound test mechanism is working correctly.

Cleaning or inspection will be required in case of contamination by very fine cement or due to wear.