Mastercure - Air Curing Box

Low cylinder breaks may be the result of improper initial curing during the first 24/48 hours and are not necessarily indicative of bad concrete. When low breaks occur, precious time is lost investigating if the low break is a result of bad concrete or just a bad test. Either way someone pays a high cost and the project is delayed.

Low cylinder breaks may be the result of improper initial curing during the first 24/48 hours and are not necessarily indicative of bad concrete. When low breaks occur, precious time is lost investigating if the low break is a result of bad concrete or just a bad test. Either way someone pays a high cost and the project is delayed.

Many curing boxes are either underpowered or poorly designed and fail to maintain critical curing conditions of temperature and moisture while cylinders wait for collection. The tough construction environment wreaks havoc on converted chest freezers and plastic coolers. Your critical test specimens should not be stored in boxes using repurposed components.

MasterCure is different. It is built to perform and survive.

AS1012.8 is the Australian standard that covers the preparation and curing of samples for compressive strength testing. The curing temperature required is defined by region, within the Tropical zone curing is to be at 27°C and within the Temperate zone curing is at 23° C. While, NZS 3112.2 is the New Zealand standard that discusses the moulding and curing concrete test cylinders.

MasterCure is a reliable means of achieving the required curing temperature for all samples cast in construction site. It meets the ASTM C31 curing specifications for the first 24/48 hours.

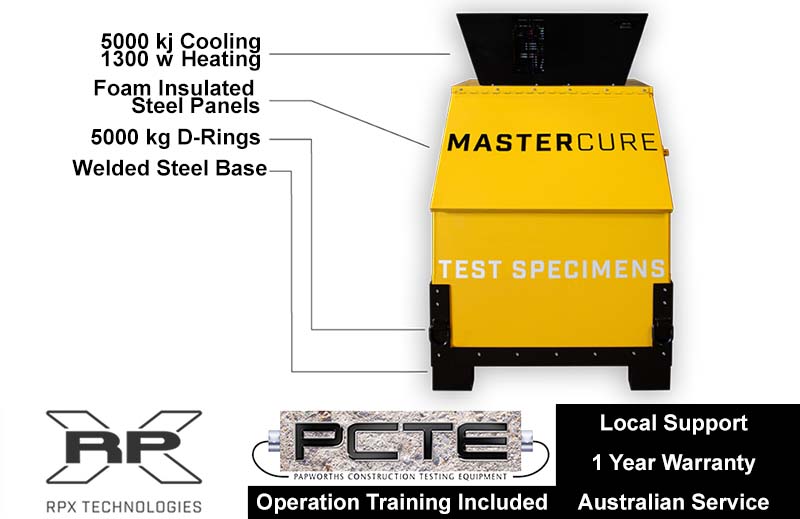

Key Features

Flexible Capacity

The MasterCure holds twenty two 150mm or forty two 100 mm cylinders without stacking and can handle cylinders, cubes and beams of all sizes. Customers often incorporate their own racks that increases capacity even further.

The MasterCure holds twenty two 150mm or forty two 100 mm cylinders without stacking and can handle cylinders, cubes and beams of all sizes. Customers often incorporate their own racks that increases capacity even further.

Powerful Performance

A 5000 BTU forced air unit provides all the cooling power needed to keep test specimens within specification. Air within the unit is continuously circulated, cycling the entire volume every 45 seconds. When temperatures outside drop, MasterCure’s 1000 Watt heater is ready to keep specimens safe and within spec until they are transported to the lab.

Elite Toughness

MasterCure is made to survive the jobsite. No other curing box is built this tough. 18-gauge steel walls protect your samples and your curing box. A 3/16-inch steel base rides on 3x4 welded steel resting blocks providing MasterCure with the strongest foundation in the industry.

True Jobsite Portability

A sturdy base allows forklift or Skytrac access from all four sides. The 5,400 kg capacity D-Rings are welded at each corner so MasterCure can be safely and efficiently moved via crane to any location.

Easy Sample Access

Each MasterCure features a wide hinged easy access door that stays open with a locking arm. This allows workers to check, add or remove samples while the door is held securely open. Easier is better!

Technical Specification

| Specifications | |

| Specimen Capacity | 42 (Ø100X200mm Cylinders) w/o stacking 22 (Ø150X300mm Cylinders) w/o stacking 16 (150x150mm Cubes) w/o stacking |

| Exterior Dimensions (L x W x H) | 914 x 914 x 1562 mm |

| Interior Dimensions (L x W x H) | 838 x 838 x 978 mm |

| Unit Weight | 159 kg |

| Power Requirements | 115V / 60Hz – 20A Dedicated Circuit |

| Integrated Level | Yes |

| Cooling Unit | 5000 BTU Forced Air Unit |

| Heating Element | 1300 W |