Automatic Cement Compression and Flexure Testing Machines

Utest's automatic range of single testing chamber and double testing chamber compression and flexure testing machines have been designed for reliable and consistent testing of mortar samples.

These compression and flexure testers conform to the current standards AS/NZS 2350.11, Methods of testing portland, blended and masonry cements, Method 11: Compressive strength and international standards like EN 196-1, 459-2, 1015-11, 13454- 2; ASTM C 109, C348, C349 and BS 3892-1, 4551-1.

Accessories such as compression and flexure jigs and distance pieces should be ordered separately.

Operators may control the following paramerters with the touchscreen control unit.

- Pace rate control from 50 N/sec (flexture) to 2,4 kN/sec (compression)

- Class 1 and Class A starting from with the 1 % for 250 kN and 15 kN capacity

- Closed loop control with automatic test procedure.

- Load control pace rates

- Stand-Alone control or computer control

- Free of charge Utest software(USOFT-4830.FPR) for the tests

- Load cells for force measurements

U-Touch PRO Control Unit

The UTC-4930.FPR Control Unit is designed to perform compression, flexure and splitting tensile strength tests of construction materials such as cement mortar, concrete and masonary units/blocks. Tests will require a JIg that matches the desired Australian of International Test standard

All the operations of U-Touch PRO are controlled from the front panel touch screen display, supporintg charts of "Load vs. Time", or "Stress vs. Time".

UTEST Software

USOFT-4830.FPR software provides a computer link to operate Compression and Flexural tests to standard.

Safety Features

- Maximum pressure valves to avoid machine overloading

- Piston travel limit switch

- Emergency stop button

- Software controlled maximum load value

- Removable transparent front-rear safety doors (Factory installed and ordered separately)

Maximum horizontal clearance for placing sample is limited with the border of the platens. Sample must be placed such that its ends will not overlap the ends of platens and it must be centered perfectly. The suitable vertical clearance for specimen can be adjusted with distance pieces.

Dual Stage Pump

On a dual stage pump, a high delivery, low pressure gear pump is used for rapid approach, while a low delivery, high pressure radial piston pump is used for test execution. The Rapid approach facility shortens the time interval from piston start until the upper platen touches to the specimen.

This feature helps to save a lot of time when a large number of specimens are going to be tested.

| Model | UTCM-3722.FPR | UTCM-3742.FPR | |

| Test Type | Compression | Flexure | Compression |

| Capacity | 250 kN | 15 kN | 250 kN |

| Class 1 Measuring Range | 2.5 to 250 kN | 0.15 to 15 kN | 2.5 to 250 kN |

| Platen Roughness | ≤3.2 μm | ≤3.2 μm | ≤3.2 μm |

| Lower Platen Dimensions | 165 mm | 165 mm | 165 mm |

| Upper Platen Dimensions | 165 mm | 165 mm | 165 mm |

| Vertical Clearance Between Platens | 237 mm | 237 mm | 237 mm |

| Piston Diameter | 160 mm | 160 mm | 160 mm |

| Maximum Piston Movement | 20 mm | 20 mm | 20 mm |

| Horizontal Clearance | 300 mm | 274 mm | 266 mm |

| Power | 750 W | 750 W | |

| Oil Capacity | 20 L | 20 L | |

| Maximum Working Pressure | 125 bar | 30 - 125 bar | |

| Rapid Approach Rate | 50 mm/min | 80 mm/min | 50 mm/min |

| Dimensions (WxLxH) | 830 x 500 x 1650 mm | 1020 x 500 x1580 mm | |

| Weight | 265 kg | 365 kg | |

Maximum horizontal clearance for placing a sample is limited with the border of the platens. Sample must be placed such that its ends will not overlap the ends of platens and it must be centered perfectly. The suitable vertical clearance for specimens may be adjusted with distance pieces.

Other Available Systems

Manual and Semi-Automatic hydraulic power packs are also available. UTEST also produce a range of advanced servo-controlled Automatic Power Packs with proportional valve.

Safety Features

- Maximum pressure valves to avoid machine overloading

- Piston travel limit switch

- Emergency stop button

- Software controlled maximum load value

Accesories

Testing Jigs

| Product Code | Sample Size | Standard | Image |

| UTCM-4210E | 40 x 40 x 160 mm | AS and EN |  |

| UTCM-4200E | 40 x 40 x 160 mm | AS and EN |  |

| UTCM-4210A | 50x50x50 mm | ASTM |  |

| UTCM-4200A | 150 x 150 x 750 | ASTM |  |

| UTCM-4210B | 70.7 x 70.7 x 70.7 mm | BS |  |

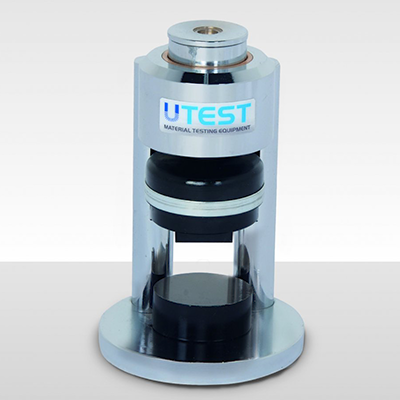

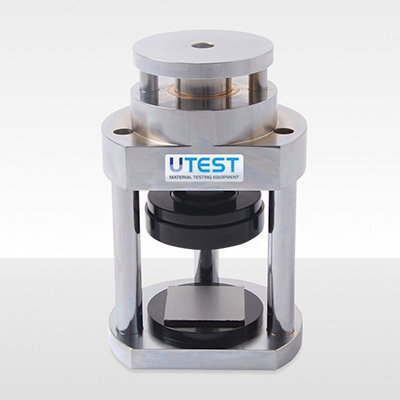

Tensile Adhesion Strength Test Apparatus

The UTCM-4223 Tensile Adhesion Strength Test can be fitted to the UTEST Cement Compression or Compression / Tension testing machines. This apparatus is supplied complete with 5 kN load cell and should be installed at our factory.