CorroWatch - Embeddable Corrosion Front Probes

The CorroWatch acts as an early warning system to predict the initial stages of corrosion in concrete structures. It is cast into the cover concrete, normally in newly cast concrete structures. The sensor can measure most of the relevant corrosion parameters.

The CorroWatch acts as an early warning system to predict the initial stages of corrosion in concrete structures. It is cast into the cover concrete, normally in newly cast concrete structures. The sensor can measure most of the relevant corrosion parameters.

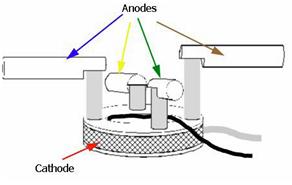

The CorroWatch is a multi-sensor, which in the standard version consists of four black steel anodes and one noble metal cathode. The anodes are placed in varying, but defined distances from the exposed concrete surface. The height of the anodes is flexible and can be adjusted according to the concrete cover thickness.

Figure 1 – Photo of CorroWatch Probe Installed

The CorroWatch sensor is acting as a macrocell measuring the corrosion activity between the corroding (anodic) and not corroding (cathodic) on the metal surface.

The CorroWatch sensor is acting as a macrocell measuring the corrosion activity between the corroding (anodic) and not corroding (cathodic) on the metal surface.

By measuring the corrosion current and also electrochemical potential in different depths in the concrete cover it is possible to predict when the corrosion should reach the reinforcement and thus prepare the necessary maintenance measures in time before the damage occurs.

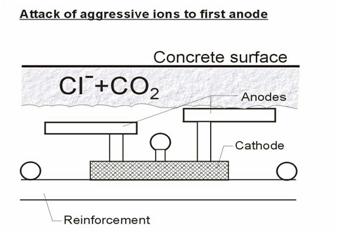

Figure 2 – CorroWatch Probe with 4 anodes shown

Figure 3 – Chlorides and Carbonation approaching the Anodes

To predict when the reinforcement corrosion will start corroding different measurements techniques could be chosen. First and foremost it could be done by means of electrochemical potential measurements against a stable reference electrode. The current is measured, either with a volt-meter or a specially designed data logger (ie CorroZoa). When corrosion starts, the current will increase significantly.

The CorroWatch sensors allow use of both options for measurements of corrosion current. However the use of zero resistance Ammeter technique is to be preferred. In the beginning before corrosion occurs on the anode the measured corrosion current is very small. When the passive layer is broken and corrosion is initiated the measured corrosion current increase rapidly.

STRUCTURE

The CorroWatch multi-probe is composed of: 4 anodes, 1 cathode, 1 reinforcement connection and an internal temperature sensor. The 4 anodes are placed in a joint ring in varying but well known distance to the ring’s bottom. The cathode is placed in the ring’s periphery.

To obtain optimum evaluation possibilities, we recommend the CorroWatch probe to be mounted in combination with an ERE-20 reference-electrode.

The cables from the CorroWatch probe and the ERE-20 reference-electrode are joined and conducted to the concrete surface. To protect against casting damage, it might be advantageous to conduct the cables in conduits.

AREAS OF USE

- Areas difficult to access, e.g. tunnels.

- Bridges in marine environments.

- Splash zones, e.g. pillars in sea water.

- Desalination Plants and Sea Ports

POSITION

It is recommended to install the CorroWatch probe in the concrete cover between the concrete surface and the outer reinforcement layer. To ensure correct function it is extremely important that great care is taken when mounting the CorroWatch probe. It is important that the position of the probe does not change during casting. This is ensured in the best way by e.g. mounting the probe on at least two reinforcement bars.

CorroZoa

The CorroZoa is a data logging Zero Ohm Ammeter designed for compatibility with Force’s CorroWatch and CorroRisk chloride monitoring probe systems.

The CorroZoa is a data logging Zero Ohm Ammeter designed for compatibility with Force’s CorroWatch and CorroRisk chloride monitoring probe systems.

The CorroZoa will measure half-cell potential, corrosion current, and temperature. The unit can either be used manually or automated and left as a data logger.

EXAMPLE

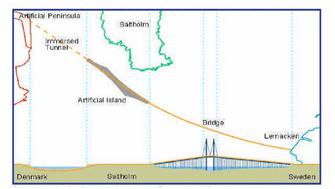

The adjacent picture shows a CorroWatch multi-sensor which has been installed for monitoring of time to corrosion initiation in the immersed elements of Øresund tunnel connecting Denmark and Sweden.

The adjacent picture shows a CorroWatch multi-sensor which has been installed for monitoring of time to corrosion initiation in the immersed elements of Øresund tunnel connecting Denmark and Sweden.

In each of the chosen tunnel elements 21 CorroWatch were installed together with 27 ERE 20 reference electrodes. In total 189 CorroWatch were installed in 9 tunnel elements. The CorroWatch were installed in such a way that the concrete cover on the highest electrode (anode) is approximately 25 mm from the concrete surface.

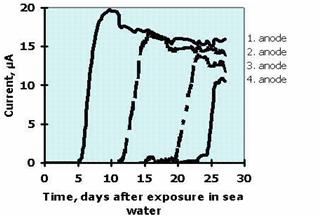

In figure 5 an example from a laboratory test is shown indicating when the corrosion initiates at each of the 4 anodes.

In figure 5 an example from a laboratory test is shown indicating when the corrosion initiates at each of the 4 anodes.

Figure 4 - Image showing the Location of the Øresund Tunnel

Figure 5 – Data from 4 anodes over 30days exposure

SPECIFICATIONS

The standard CorroWatch probe is supplied with specifications as follows:

|

Body Diameter |

Ø75 mm |

|

Height |

48 mm |

|

Width |

160 mm |

|

Anode Length |

60 mm |

|

Anode Diameter |

Ø12 mm |

|

Overall Weight |

0.5 kg |

|

Cable Type |

Screened 8-conductor |

|

Length |

5m (extendable) |

|

Anode Heights |

|

|

Anode 1 |

48 mm high |

|

Anode 2 |

43 mm high |

|

Anode 3 |

38 mm high |

|

Anode 4 |

33 mm high |