Crosshole Sonic Logging - Pile Testing

Crosshole Sonic Logging (CSL), also known as cross sonic logging or the sonic logging test is the most accurate and reliable technique for assessing the integrity of deep foundation elements such as newly placed concrete drilled shafts and slurry walls, particularly when drilling below groundwater level. Considering the number of issues which can threaten the integrity of deep foundation elements during construction, it is essential to adopt a high level of quality control and assurance. The CSL testing procedure can detect anomalies inside concrete within just minutes.

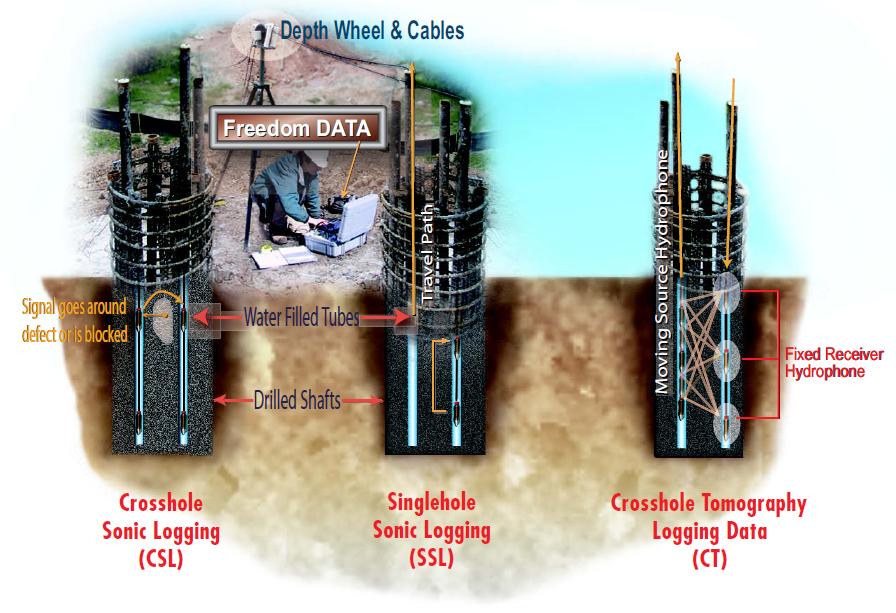

Crosshole Tomography (CT) is a higher resolution analysis which can be used for further investigations after CSL has detected a flaw. Pile tomography delivers unmatched accuracy for defining the size, shape, severity and location of defects. CSL and CT analysis can eliminate the questions and concerns associated with problematic concrete pours.

The Problem

The number of issues which threaten the integrity of drilled shafts and slurry walls are extensive. Necking and caving in of drilled shafts, reinforcing cage buckling, pile damage, tremie ‘burping’ and excess water intrusion can all have serious effects on structural integrity. Being able to perform QA promptly after the concrete pour can save a substantial amount of time and money compared with late detection of flaws. Having the ability to assess the exact scope of defects will ensure efficient remedial measures.

Applications

CSL and CT can be applied to any structure which supports the transmission of ultrasonic waves. This includes concrete, slurry and grout placed either above or below the waterline. The tests can be applied to concrete drilled shafts, auger cast piles, slurry walls or any mass concrete pour where QA is a priority.

Advantages

- Quick and safe – CSL tests performed in less than 5 minutes

- Can perform tests for above and below waterline structures

- Identify and locate the presence of multiple defects

- CT can deliver high-resolution images with unsurpassed accuracy and interpretation simplicity

- Perform QA regarding the presence of poor quality concrete, voids, honeycombing and soil intrusion

- Identify the size, shape, severity, nature and location of anomalies

How it works

1. Installing Access Tubes

Access tubes must be installed before construction and filled with water. These are typically 38 to 50mm diameter PVC or steel tubes tied to the inside of the rebar cage. The number of tubes required depends on the structure’s size and the resolution required.

2. Taking Readings

The source and receiver hydrophones are lowered to the bottom of separate tubes. As the hydrophones are simultaneously lifted, the horizontal ultrasonic pulse velocity is measured. The depth wheel controls the sample reading resolution which is typically taken at 6cm intervals.

3. Interpreting Results

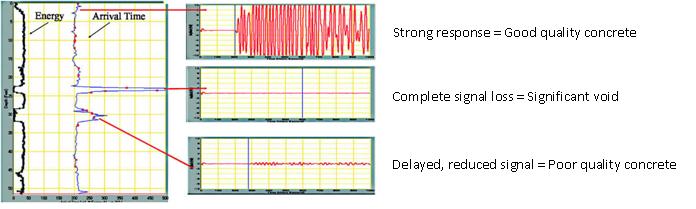

Uniform, good quality concrete will promote propagation of ultrasonic waves. Longer ultrasonic wave travel times and lower amplitudes correspond to poor quality or voided concrete. A complete loss in signal means a substantial void is hindering the transfer of the signal between the hydrophones. Refer to the figure below for an example results readout.

4. Further Investigation

4. Further Investigation

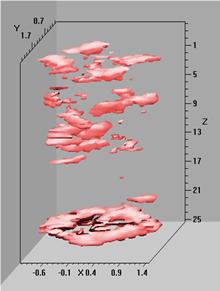

If multiple access tubes are installed, then the perimeter pairs and sub-diagonal tube pairs can be used to further define the 2D image of any anomalies. In addition CT uses differential height measurements to deliver a complete 3D internal image of the structure (see image right).

Platform

CSL and CT require the Freedom Data PC as shown at the top of the page. It allows for mobility and onsite analysis. Please see the Freedom Data PC page for more in depth specifications on this platform. Other equipment supplied includes the hydrophones and depth wheel.

Relevant Standards

- ASTM D6760-02

- ACI 228.2R

- FLH 521.830

Versatility

By utilising the same set of water-filled access tubes, both CSL and CT can give invaluable information regarding the quality of concrete between these tubes. Single Hole Sonic Logging (SSL) as presented in the figure to the right, provides additional information regarding concrete quality around the vicinity of an individual tube. This allows QA analysis beyond the perimeter of the rebar cage giving a complete cross-sectional analysis.