DY-2 Pull Off Tester

The DY-2 family of automated pull-off testers covers the complete range of pull-off applications with unmatched ease of operation and a unique capability to store a complete record of the test.

The DY-2 family of automated pull-off testers covers the complete range of pull-off applications with unmatched ease of operation and a unique capability to store a complete record of the test.

The DY-2 is further unique in that it records every single test parameter required by the specification.

- Time and date of the test

- Test disc size

- Maximum load applied

- Automatic calculation of bond strength

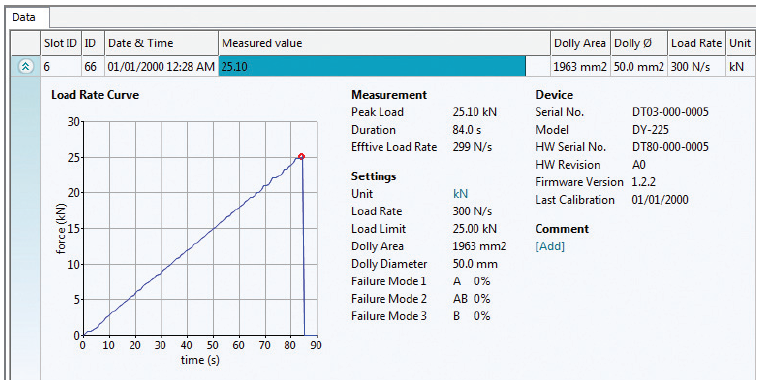

- Applied load rate with graphical record

- Complete time of test

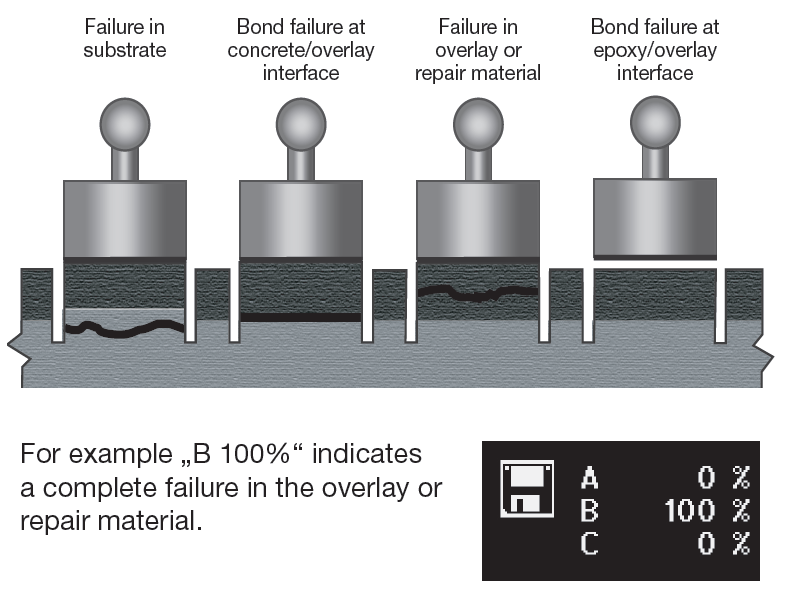

- Failure mode

For the very first time, the operator is able to provide a complete record of the pull-off test, proving that the test was carried out in accordance with the applicable standard.

Three versions of DY-2 are available differentiated by maximum pulling force. This covers the complete range of pull-off applications (examples for Ø 50mm test discs) for normal, low strength such as mortar or high strength such as carbon fibre reinforced polymer.

DY – 2 Models

| Model | Working Range* | Description | |

| Tensile Force | Pressure (Test Disk Ø 50 mm) | ||

| DY-206 | 0.6 - 6 kN | 0.3 - 3.1 MPa | DY-206 has increased accuracy for low strength applications such as testing adhesive strength of mortars and renders. |

| DY-216 | 1.6 - 15.5 kN | 0.81 - 7.8 MPa | DY-216 covering most applications. |

| DY-225 | 2.5 - 25 kN | 1.3 - 12.7 MPa | DY-225 for very high strength applications such as testing of fibre reinforced polymers bonded to concrete structures or testing the bond strength of repair and overlay materials. |

Features

Features

- Integrated, feedback controlled motor removes operator variations by fully automated testing at a constant load rate which can be verified.

- Full data logging including failure mode entry options for up to

- Automatic calculation of strength for different test discs without re-calibration of system

- DY-Link software displays a complete record of test including load rate graph

- Wide range of test disks/dollies

Applications

- Concrete or shotcrete tensile strength measurement

- Measuring the bond of overlays, renders or repairs

- Coating adhesion

- Pull off testing is also used for exotic testing applications such as testing the integrity of laminated carbon brake disks

Benefits

Benefits

- Failure mode reporting – The DY-2 is unique in allowing the operator to record the location of the break during a test in the same record as the strength measurement.

- Six months mechanical and 2-year electronic component warranty

- DY-2 is calibrated to EN ISO 7500-1 Class 1, this calibration exceeds the accuracy requirements of all standards stated later in this brochure

Accessories

Test Discs

| Size (mm) | Materials | No | Thread |

| 20Ø | Al | 10 | M10 |

| 50Ø | Al or Fe | 10 | M10 |

| 75Ø | Al | 5 | M10 |

| 100Ø | Al | 3 | M10 |

| 50 x 50 | Al | 10 | M10 |

| 40 x 40 | Al | 10 | M10 |

| 100 x 100 | Al | 3 | M10 |

Technical Specifications

| Accuracy and Resolution | EN ISO 7500-1 Class 1 (±1%) |

| Memory capacity | 100 measurements |

| Battery capacity | 1500 mAh, 3.7V (min. 80 measurements) |

| Charger connection | USB type A (5V, 500mA) |

| Weight | 4.5 kg |

| Dimensions of housing | 109 x 240 x 205.5 mm |

| Operating temperature | -10 to 50°C (32 to 122°F) |

| Storage temperature | -10 to 70°C (14 to 158°F) |

Applicable Standards

- ISO 4624 CEN/TC 125

- EN 1452/1015-12/1348

- ASTM C 4541 / ACI 503-30

- ASTM D 7234-05 / D7522 / D4541

- ZTV-SIB 90

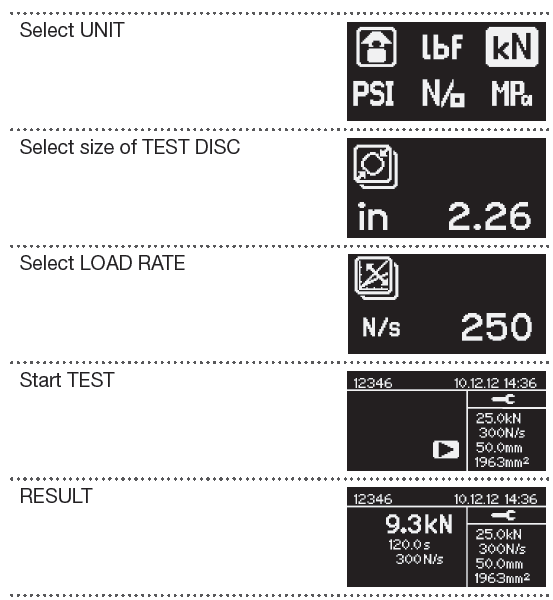

Menu System Illustration