California Bearing Ratio [CBR] Test Machines

The California Bearing Ratio (CBR) test is a measure of the strength of subgrade soil and highway sub base and subgrade via a penetration test.

The California Bearing Ratio (CBR) test is a measure of the strength of subgrade soil and highway sub base and subgrade via a penetration test.

It is designed for testing cohesive materials with a particle size less than 19mm, in Australia the governing standard is AS 1289.6.1.

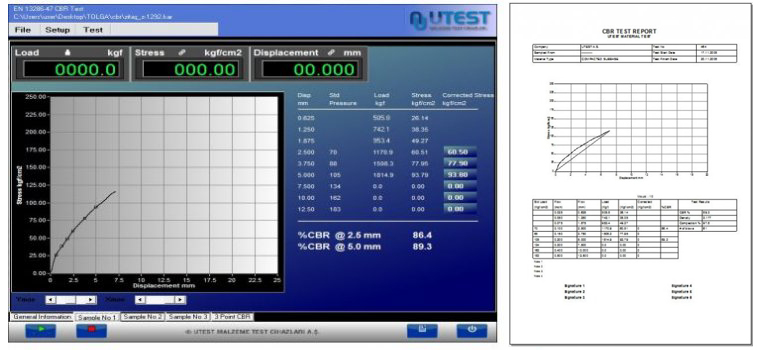

Automatic CBR Test Machine

Utest's dedicated, automatic CBR machine is composed of a robust and compact two column frame with an adjustable upper crossbeam driven by an electromechanical ram of maximum 50 kN capacity and a data acquisition and processing system.

Rapid adjustment of the platen is also provided by up and down buttons which are located on the front panel of the machine.

The model is supplied complete with a 50 kN load cell, penetration piston, linear potentiometric displacement transducer (25 mm x 0.001 mm).

Multiplex Machine with CBR Fixtures

An alternative to a single purpose machine is a Multiplex Machine with accessories for CBR. The specifications are similar to a single purpose device, but the unit can also complete unconfined compressive strength of soil, and varied asphalt tests. For more details please visit the dedicated product page.

Datalogging and Outputs

The U-Touch Pro control unit will provide a real time graph of test parameters and operates the system in displacement control. Alternatively, an operator can use dedicated computer software to collect data during tests and export raw measurements or custom pdf reports of the outcome.

Field Testing Systems

Field Testing Systems

Onsite evaluation of base and sub base is achievable due to field CBR testing. Sites un-disturbed by construction activity are most preferred when performing the field test. It is also possible to saturate test sites to collect conservative data.

It is also possible to assemble the machine with conversion frame UTS-0867 to create a mechanical CBR test machine.

Accessories

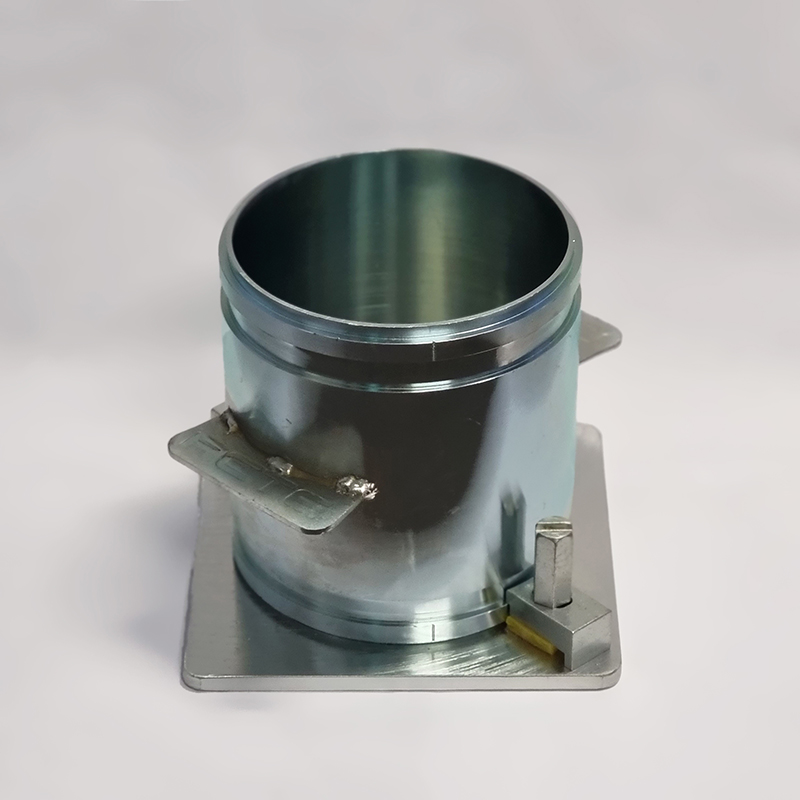

CBR Moulds

Designed in response to feedback from labs Australia and NZ wide, our mould is the new winner for performance and cost.

Designed in response to feedback from labs Australia and NZ wide, our mould is the new winner for performance and cost.

- Improved durability and usability

- Compliant with AS & NZ standards

- Fully Galvanised

- Simple to clean and maintain

- Durable PU Plastic instead of metal springs at fixtures

- Rim markings for tripod alignment

- Common hexagonal bolt for use with spanner or screwdriver

- Quick-Release Collar design

- Easier to lift with two handles

- Automatic Compactor indexing recess at bottom of base plate

| Product Code | Description |

| SOI-05 | CBR Mould (PCTE Brand) California Bearing Ratio to AS1289-6.1.1 and AS1289.6.1.2 |

| SOI-06 | CBR Mould Collar (PCTE Brand) Collar for Mould. Mould sold separately. California Bearing Ratio to AS1289-6.1.1 and AS1289.6.1.2 |

| UTS-0705A | Spacer Disc with T handle, 150.8 mm dia. x 61.4 mm height |

| UTS-0708A | Annular Surcharge Weight, 2.27 kg |

| UTS-0710A | Slotted Surcharge Weight, 2.27 kg |

| UTS-0712A | CBR Solid Base Plate |

| UTS-0724 | Straightedge 300x30x5 mm |

| UTS-0729 | Filter Paper for CBR Test No:5 x 150 mm dia. (Pack of 100) |

| UTS-0730 | Filter screen, 144 mm dia. 150 μm mesh ASTM |

Automatic Compactor – UTS-0650-T

Automatic chain drive compactor. The total number of blows and the count of internal and external decreases of mass are determined by a programmable counter.

Supplied with hammers of weight suitable for 100 and 150 mm compaction moulds and Australian Standard CBR moulds.

Please see the dedicated webpage for more details.

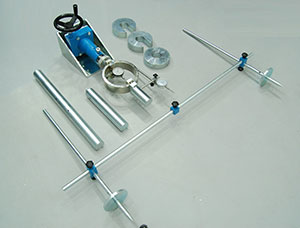

Swell Plate and Gauge

Swell Plate and Gauge

Used to observe the swell of a soaking soil sample. As the perforated plate rises a dial gauge displays the swell

Sample Extruders

Extruders are available for CBR, compaction and Proctor moulds along with standard BSP [U4] sample tubes. PCTE offers both manual jack and automated extruders.

Soil Lathe/Trimmer and Extruder - UTS-0160

The UTS-0160 Soil Lathe, Trimmer and Extruder is used to extrude and trim soil samples from 35 mm to 100 mm diameter to reduce samples.

Technical Specifications

Automatic CBR Test Machine Specifications

| Specification | |

| Model (mm) | UTS-0856.ACPR |

| Dimensions L x W x H (mm) | 645 x 470 x 1140 |

| Weight | 80 |

| Current Specifications (mm) | 220 V 50 Hz, 1 ph |

| Motor (kW) | 0.75 |

| Test Speed Range (mm/min) | 0.5 > 5 |

| Max Horizontal Clearance (mm) | 260 |

| Max Vertical Clearance(mm) | 690 |

| Min Vertical Clearance (mm) | 260 |

| Max Ram Stroke (mm) | 100 |

Applicable Standards

EN 13286-47

BS 1377:4

ASTM D1883

AS1289.6.1